Sharaxaadda Badeecada

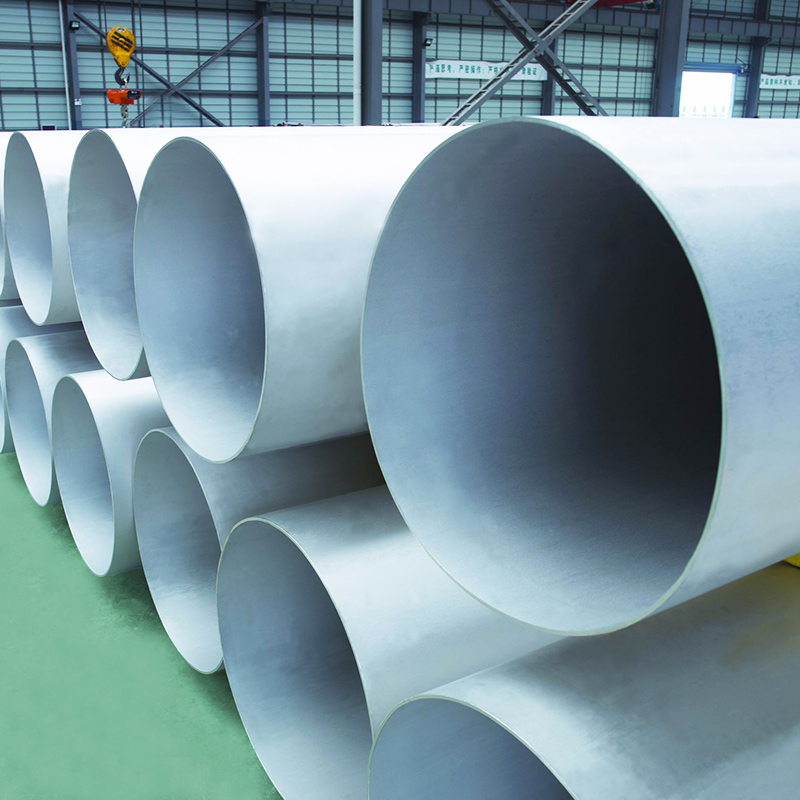

Tuubooyinka birta aan lahayn ee la isku tolay waa qaybo muhiim u ah warshado kala duwan sababtoo ah cimri dhererkooda, iska caabintooda daxalka, iyo kala duwanaanshahooda. Tuubooyinkan waxaa lagu sameeyaa habka alxanka, iyagoo isku daraya xaashiyo bir ah oo aan lahayn ama xargo si ay u sameeyaan tuubooyin dhululubo ah. Waa kan dulmar guud oo ku saabsan tuubooyinka birta aan lahayn:

Qalabka iyo Darajooyinka:

● Taxanaha 304 iyo 316: Darajooyinka birta aan daxalka lahayn ee guud ahaan loo isticmaalo.

● 310/S iyo 310H: Bir aan miridh lahayn oo heerkul sare u adkaysata oo loogu talagalay isticmaalka foornada iyo beddelka kulaylka.

● 321 iyo 321H: Darajooyinka u adkaysta kulaylka oo ku habboon jawiga heerkulka sare.

● 904L: Daawaha aadka u adkaysta daxalka ee loogu talagalay deegaannada gardarrada leh.

● S31803: Bir aan miridh lahayn oo laba jibbaaran, oo bixisa iska caabin xoog iyo daxal labadaba.

Habka Wax Soo Saarka:

● Alxanka Isku-dhafka Korontada (EFW): Habkan, tolmo dheer ayaa lagu tolaa iyadoo tamar koronto lagu shubayo qaansada alxanka.

● Alxanka Qaanso ee Qulqulka ku Jira (SAW): Halkan, alxanka waxaa lagu sameeyaa dhalaalinta geesaha iyadoo la adeegsanayo qaanso joogto ah oo ku dhex jirta qulqulka.

● Alxanka Soo-kicinta Heerka Sare (HFI): Habkani wuxuu adeegsadaa durdurro soo noqnoqda sare leh si uu u abuuro tolmo alxan ah oo joogto ah.

Faa'iidooyinka:

● Iska caabbinta daxalka: Waxay u adkaysataa noocyo badan oo warbaahin iyo deegaanno ah oo daxal leh.

● Xoog: Xoog farsamo oo sare ayaa hubiya daacadnimada qaab-dhismeedka.

● Kala Duwanaansho: Waxaa laga heli karaa cabbirro kala duwan, darajooyin, iyo dhammaystiryo si ay ugu habboonaadaan codsiyada kala duwan.

● Nadaafad: Si fiican ugu habboon warshadaha leh shuruudaha nadaafadda ee adag.

● Dheeraanshaha: Waxay muujisaa cimri dherer oo heer sare ah, taasoo keenta cimri dheer.

Marka la soo koobo, tuubooyinka birta aan miridhku lahayn ee la alxameeyay waa qaybo muhiim u ah warshadaha oo dhan, iyagoo bixiya cimri dherer, iska caabin daxalka, iyo kala duwanaansho loogu talagalay codsiyada kala duwan. Xulashada saxda ah ee heerka, habka wax soo saarka, iyo u hoggaansanaanta heerarka warshadaha ayaa muhiim u ah hubinta waxqabadka ugu wanaagsan iyo badbaadada nidaamyada tuubooyinka alxamaysan.

Tilmaamaha

| ASTM A312/A312M:304, 304L, 310/S, 310H, 316, 316L, 321, 321H iwm... |

| EN 10216-5: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 iwm. |

| DIN 17456: 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4432, 1.4435, 1.4541, 1.4550 iwm... |

| JIS G3459: SUS304TB, SUS304LTB, SUS316TB, SUS316LTB iwm... |

| GB/T 14976: 06Cr19Ni10, 022Cr19Ni10, 06Cr17Ni12Mo2 |

| Bir aan miridh lahayn oo Austenitic ah:TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Bir aan daxal lahayn oo laba jibbaaran:S31803, S32205, S32750, S32760, S32707, S32906... Daawaha Nikkel:N04400, N06600, N06625, N08800, N08810(800H), N08825... Isticmaalka:Warshadaha wax soo saarka ee Batroolka, Kiimikada, Gaaska Dabiiciga ah, Korontada iyo qalabka farsamada. |

| DN mm | NB Inji | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12" | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14" | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18" | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22" | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28" | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32" | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm iyo wixii ka sareeya DN dhumucda derbiga tuubada waa in loo habeeyaa | ||||||||||||||||

Heerka & Darajada

| Heerka Caadiga ah | Darajooyinka Birta |

| ASTM A312/A312M: Tuubooyinka Birta aan lahayn si aan kala go 'lahayn, la alxamay, oo si aad ah u qabow oo loo shaqeeyay. | 304, 304L, 310S, 310H, 316, 316L, 321, 321H iwm... |

| ASTM A269: Tuubo bir ah oo aan kala go 'lahayn oo aan lahayn bir austenitic ah oo loogu talagalay adeegga guud | TP304, TP304L, TP316, TP316L, TP321.TP347 iwm... |

| ASTM A249: Kuleyliyaha Birta Austenitic ee Alxanka leh, Kuleyliyaha Sare, Beddelaha Kulaylka, iyo Tuubooyinka Kondensarka | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A269: Tuubooyinka Birta aan sinayn oo aan la alxanayn oo leh Dhexroor yar | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A270: Tuubo Nadaafad ah oo Bir aan kala go 'lahayn oo aan la taaban karin oo bir ah oo Ferritic/Austenitic ah oo aan lahayn bir aan lahayn bir | Birta Aan Daxalka Ahayn ee Austenitic: 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 Bir aan miridh lahayn oo Ferritic/Austenitic ah (Duplex) ah oo aan miridh lahayn: S31803, S32205 |

| ASTM A358/A358M: Shuruudaha Tuubooyinka Birta Austenitic ee la alxamay ee loogu talagalay Deegaannada Heerkulka Sare, Cadaadiska Sare, iyo Daxalka leh | 304, 304L, 316, 316L, 316H, 316N, 316LN, 317, 317L, 321, 321H, 347, 347H, 348 |

| ASTM A554: Tuubo farsamo oo bir ah oo aan daxal lahayn oo la alxamay, oo badanaa loo isticmaalo codsiyada qaab-dhismeedka ama qurxinta | 304, 304L, 316, 316L |

| ASTM A789: Tuubo bir ah oo aan kala go 'lahayn oo aan lahayn bir bir ah oo bir ah oo loogu talagalay adeegga guud | S31803 (Bir aan daxal lahayn oo laba jibbaaran) S32205 (Bir aan daxal lahayn oo laba jibbaaran) |

| ASTM A790: Tuubo bir ah oo aan kala go 'lahayn oo aan lahayn bir ferritic/austenitic ah oo loogu talagalay adeegga guud ee daxalka, adeegga heerkulka sare, iyo tuubooyinka birta aan daxalka lahayn ee laba-jibbaaran. | S31803 (Bir aan daxal lahayn oo laba jibbaaran) S32205 (Bir aan daxal lahayn oo laba jibbaaran) |

| EN 10217-7: Tuubooyinka birta aan miridhku lahayn ee la alxamay Shuruudaha wax soo saarka ee Heerka Yurub. | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 iwm... |

| DIN 17457: Heerka Jarmalka ee loo isticmaalo soo saarista tuubooyinka birta aan miridhku lahayn | 1.4301, 1.4307, 1.4401, 1.4404, 1.4571, 1.4003, 1.4509, 1.4510, 1.4462, 1.4948, 1.4878 iwm... |

| JIS G3468: Heerka Warshadaha Jabbaan kaas oo qeexaya shuruudaha wax soo saarka ee tuubooyinka birta aan daxalka lahayn ee la alxamay. | SUS304, SUS304L, SUS316, SUS316L, SUS329J3L iwm. |

| GB/T 12771: Heerka Qaranka ee Shiinaha oo loo isticmaalo shuruudaha wax soo saarka ee tuubooyinka birta aan miridhku lahayn. | 06Cr19Ni10, 022Cr19Ni1, 06Cr17Ni12Mo2, 022Cr22Ni5Mo3N |

| Bir aan miridh lahayn oo Austenitic ah: TP304, TP304L, TP304H, TP310S, TP316, TP316L, TP316H, TP316Ti, TP317, TP317L, TP321, TP321H, TP347, TP347H, TP347HFG N08904(904L), S30432, S31254, N08367, S30815... Bir aan daxal lahayn oo laba jibbaaran: S31803, S32205, S32750, S32760, S32707, S32906... Nikkel Daawaha:N04400, N06600, N06625, N08800, N08810(800H), N08825... Isticmaalka: Warshadaha wax soo saarka ee Batroolka, Kiimikada, Gaaska Dabiiciga ah, Korontada iyo qalabka farsamada. | |

Xakamaynta Tayada

Hubinta Walxaha Cayriin, Falanqaynta Kiimikada, Imtixaanka Farsamada, Kormeerka Muuqaalka, Hubinta Cabbirka, Imtixaanka Laabista, Imtixaanka Saamaynta, Imtixaanka Daxalka Dhex-dhexaadka ah, Baaritaanka Aan Burburin (UT, MT, PT) Shahaadada Habka Alxanka, Falanqaynta Qaab-dhismeedka Microstructure, Imtixaanka Flaring iyo Fiditaanka, Imtixaanka Adkaanta, Tijaabada Cadaadiska, Tijaabada Waxyaabaha Ferrite, Tijaabada Metallography, Tijaabada Daxalka, Tijaabada Hadda ee Eddy, Tijaabada Buufinta Cusbada, Tijaabada Iska Caabbinta Daxalka, Tijaabada Gariirka, Tijaabada Daxalka Pitting, Rinjiga iyo Kormeerka Dahaarka, Dib u Eegista Dukumentiyada…..

Isticmaalka & Codsiga

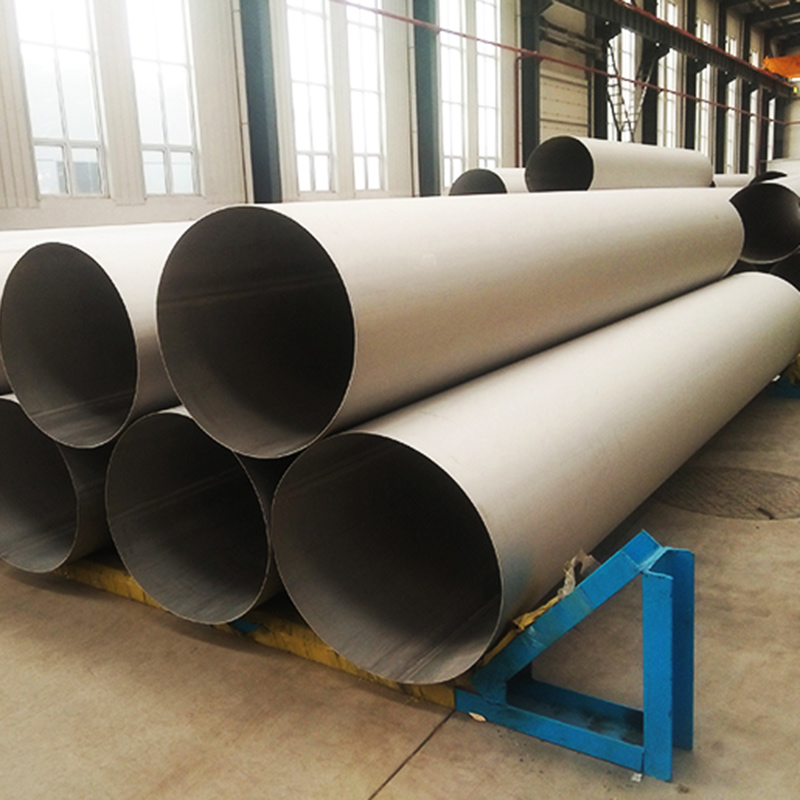

Tuubooyinka birta aan lahayn ee la alxameeyay waxay si ballaaran u isticmaalaan warshado kala duwan sababtoo ah sifooyinkooda gaarka ah iyo kala duwanaanshahooda. Tuubooyinkan waxaa loo adeegsadaa codsiyo kala duwan, waxaana sabab u ah cimri dhererkooda, iska caabbinta daxalka, iyo ku habboonaanta deegaanno kala duwan. Qaar ka mid ah meelaha muhiimka ah ee isticmaalka iyo isticmaalka tuubooyinka birta aan lahayn ee la alxameeyay waxaa ka mid ah:

● Isticmaalka Warshadaha: Caadiyan waxaa laga isticmaalaa warshadaha saliidda, gaaska, kiimikada batroolka, iyo korontada sababtoo ah iska caabbinta daxalka.

● Dhismaha: Waxaa loo isticmaalaa tuubooyinka, biyaha, iyo dhismayaasha si loo xoojiyo iyo cimri dhererkooda.

● Warshadaha Cuntada: Waa muhiim u ah gaarsiinta cuntada iyo cabitaannada, iyadoo la raacayo heerarka nadaafadda.

● Baabuurta: Waxaa loo shaqeeyaa nidaamyada qiiqa iyo qaybaha dhismaha, iyadoo la waafajinayo xaaladaha adag.

● Caafimaad: Waxaa loo isticmaalaa aaladaha caafimaadka iyo tuubooyinka nadaafadda, iyadoo mudnaanta la siinayo nadaafadda.

● Beeraha: Nidaamyada waraabka ee u adkaysta daxalka, hubinta qaybinta biyaha ee hufan.

● Daaweynta Biyaha: Ku habboon in la geeyo biyaha la daweeyay iyo kuwa milixda laga saaray.

● Badda: Waxay u adkaysataa daxalka biyaha cusbada leh, si ballaaran ayaa loogu isticmaalaa maraakiibta iyo dhismayaasha badda.

● Tamarta: Daadgureynta dareerayaasha qaybta tamarta, oo ay ku jiraan gaaska dabiiciga ah iyo saliidda.

● Bur iyo Warqad: Waa muhiim in la gudbiyo kiimikooyinka iyo dareerayaasha habka wax soo saarka.

Marka la soo koobo, tuubooyinka birta aan miridhku lahayn ee la isku tolay waxay u adeegaan qaybo muhiim ah warshado iyo codsiyo kala duwan. Iska caabbintooda daxalka, xooggooda farsamada, iyo awoodda ay u leeyihiin inay buuxiyaan shuruudaha adag ayaa ka dhigaya kuwo aan lagama maarmaan u ah kaabayaasha casriga ah, hababka warshadaha, iyo qaybaha kala duwan ee takhasuska leh.

Xirmooyinka iyo Rarista

Tuubooyinka birta aan miridhku lahayn waxaa lagu xidhaa oo lagu raraa si taxaddar leh si loo hubiyo ilaalintooda inta lagu jiro safarka. Waa kan sharraxaadda habka baakadaynta iyo rarista:

Baakadaha:

● Dahaarka Ilaalinta: Kahor inta aan la xirin, tuubooyinka birta aan miridhku lahayn waxaa badanaa lagu dahaadhaa lakab saliid ama filim ilaalin ah si looga hortago miridhku iyo dhaawaca dusha sare.

● Xidhmo: Tuubooyinka cabbirro iyo tilmaamo isku mid ah ayaa si taxaddar leh loogu xidhaa. Waxaa lagu xidhaa suunno, xargo, ama xargaha balaastikada ah si looga hortago dhaqdhaqaaqa gudaha xidhmada.

● Daboolka Dhamaadka: Daboolka dhammaadka balaastikada ama birta ah ayaa la dhigaa labada daraf ee tuubooyinka si loo siiyo ilaalin dheeraad ah darafyada tuubooyinka iyo dunta.

● Barkinta iyo Barkinta: Qalabka barkinta sida xumbo, duubka xumbo, ama kartoonka jiingadda ah ayaa loo isticmaalaa in lagu bixiyo barkinta iyo ka hortagga waxyeelada saameynta inta lagu jiro gaadiidka.

● Saxamada ama Kiisaska Alwaaxiga ah: Xaaladaha qaarkood, tuubooyinka waxaa lagu xidhi karaa sanduuqyo alwaax ah ama kiishyo si loo siiyo ilaalin dheeraad ah oo ka dhan ah xoogagga dibadda iyo maaraynta.

Rarista:

● Habka Gaadiidka: Tuubooyinka birta aan miridhku lahayn waxaa badanaa lagu raraa iyadoo la adeegsanayo noocyo kala duwan oo gaadiid ah sida gawaarida xamuulka qaada, maraakiibta, ama xamuulka hawada, iyadoo ku xiran meesha loo socdo iyo degdegga.

● Konteenareynta: Tuubooyinka waxaa lagu shubi karaa weelasha rarista si loo hubiyo in si ammaan ah oo habaysan loo maro. Tani waxay sidoo kale bixisaa ilaalin xaaladaha cimilada iyo wasakhda dibadda.

● Calaamadaynta iyo Dukumentiyada: Baakad kasta waxaa lagu calaamadeeyay macluumaad muhiim ah, oo ay ku jiraan qeexitaannada, tirada, tilmaamaha maaraynta, iyo faahfaahinta meesha loo socdo. Dukumentiyada rarista waxaa loo diyaariyaa nadiifinta kastamka iyo dabagalka.

● U hoggaansanaanta Kastamka: Maraakiibta caalamiga ah, dhammaan dukumentiyada lagama maarmaanka ah ee kastamka ayaa loo diyaariyey si loo hubiyo in si habsami leh loo maro meesha loo socdo.

● Xidhmo Ammaan ah: Gudaha gaariga ama weelka, tuubooyinka si ammaan ah ayaa loogu xiraa si looga hortago dhaqdhaqaaqa loona yareeyo khatarta burburka inta lagu jiro gaadiidka.

● Dabagalka iyo La socodka: Nidaamyada daba-galka ee horumarsan ayaa loo isticmaali karaa si loola socdo goobta iyo xaaladda rarista waqtiga dhabta ah.

● Caymiska: Iyadoo ku xiran qiimaha xamuulka, caymiska rarista ayaa laga yaabaa in la helo si loo daboolo khasaaraha ama khasaaraha iman kara inta lagu jiro safarka.

Marka la soo koobo, tuubooyinka birta aan daxalka lahayn ee aan soo saarnay waxaa lagu xidhi doonaa tallaabooyin ilaalin ah waxaana la geyn doonaa iyadoo la adeegsanayo habab gaadiid oo la isku halleyn karo si loo hubiyo inay gaaraan meeshii ay u socdeen iyagoo xaalad wanaagsan ku jira. Hababka baakadaynta iyo rarista ee saxda ah waxay gacan ka geystaan hufnaanta iyo tayada tuubooyinka la keenay.