Sharaxaadda Badeecada

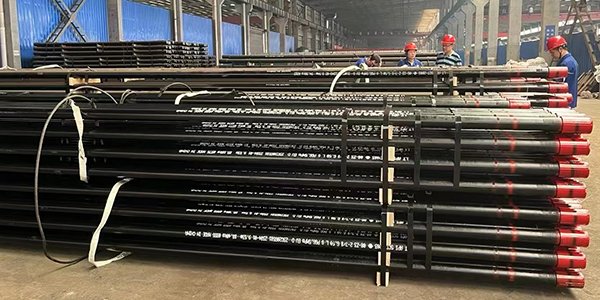

Tuubada qodista ee loo isticmaalo in lagu xiro qalabka dusha sare ee qalabka qodista iyo qalabka shiididda ama qodista, waa tuubada birta ah ee leh cidhifyo dun ah, sidoo kale waxay samaysaa isku xirka qalabka godka hoose ee qodista. Tuubada qodista badanaa waxay u qaybsantaa kelly, tuubada qodista iyo tuubo qodis culus. Tuubooyinka Qodista Birta waxay ku yimaadaan cabbirro kala duwan, xoog, iyo dhumuc derbi, laakiin badanaa waa 27 ilaa 32 cagood dherer ahaan (Range 2). Dhererka dheer, ilaa 45 cagood, ayaa jira (Range 3).

Qoorta qodista waa qaybta ugu muhiimsan ee qalabka qodista hoose, waxaana laga shaqeeyaa salka xarigga qodista. Dhumucda qoorta qodista ayaa ka weyn, sidoo kale cufnaanta iyo adkaanta ayaa ka weyn. Si loo hagaajiyo shaqada turunturada, farsamaynta godadka wiishka iyo godadka simbiriirixan ee dusha sare ee dunta gudaha ee qoorta qodista waxay noqon doontaa doorasho wanaagsan. Qoorta qodista wareegsan, qoorta qodista isku dhafan. iyo qooradaha qodista aan birlab ahayn ayaa ah qooradaha qodista ugu weyn suuqa.

Tilmaamaha

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163:10#,20#,Q345 |

| GB/T 8162:10#,20#,35#,45#,Q345 |

Heerka & Darajada

Tuubooyinka Qodista Darajooyinka Caadiga ah:

API 5DP, API Spec 7-1 E75, X95, G105 iwm...

Noocyada Isku xirka: FH, IF, NC, REG

Noocyada Mawduuca: NC26,NC31,NC38,NC40,NC46,NC50,5.1/2FH

Qalabka: Bir kaarboon/Bir aan daxal lahayn/Bir daxal leh

Tuubada qodista waa inay noqotaa mid la gaarsiin karo iyadoo loo eegayo xiriirka kor ku xusan ee heerka API5CT / Heerarka API.

Xakamaynta Tayada

Hubinta Walxaha Cayriin, Falanqaynta Kiimikada, Tijaabada Farsamada, Kormeerka Aragga, Tijaabada Xiisadda, Hubinta Cabbirka, Tijaabada Laabista, Tijaabada Fiditaanka, Tijaabada Saamaynta, Tijaabada DWT, Tijaabada NDT, Tijaabada Hydrostatic, Tijaabada Adkaanta…..

Calaamadaynta, Rinjiyeynta ka hor inta aan la keenin.

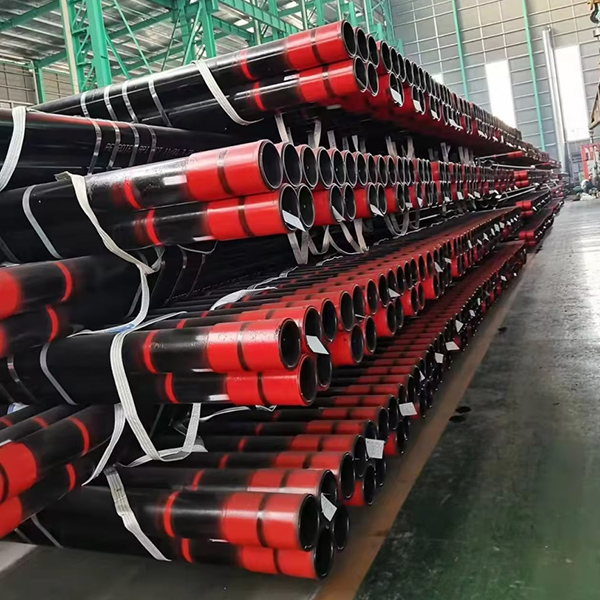

Xirmooyinka iyo Rarista

Habka baakadaha ee tuubooyinka birta ah waxaa ka mid ah nadiifinta, kooxaynta, duubista, xidhista, sugidda, calaamadaynta, baaldiyeynta (haddii loo baahdo), kaydinta weelasha, kaydinta, shaabadaynta, rarista, iyo furfurista. Noocyo kala duwan oo tuubooyinka birta ah iyo qalabka ku rakiban oo leh habab kala duwan oo baakadayn ah. Habkan dhammaystiran wuxuu hubinayaa in tuubooyinka birta ah la raro oo la gaaro meeshii loogu talagalay xaalad wanaagsan, oo diyaar u ah isticmaalkooda loogu talagalay.

Isticmaalka & Codsiga

Tuubooyinka birta ah waxay u adeegaan laf-dhabarta injineernimada warshadaha casriga ah iyo tan madaniga ah, iyagoo taageeraya codsiyo badan oo gacan ka geysta horumarinta bulshooyinka iyo dhaqaalaha adduunka oo dhan.

Tuubooyinka birta ah iyo qalabka aan soo saarnay ee Womic Steel si weyn ayaa loogu isticmaalaa dhuumaha batroolka, gaaska, shidaalka iyo biyaha, xeebaha/dhulka, mashaariicda dhismaha dekadda badda iyo dhismaha, qodista, Birta qaab-dhismeedka, mashaariicda dhismaha buundooyinka, iyo sidoo kale tuubooyinka birta saxda ah ee wax soo saarka duubista, iwm...