Sharaxaadda Badeecada

Macluumaadka Caadiga ah - ASME/ANSI B16.5 & B16.47 - Flanges-ka Tuubooyinka iyo Qalabka Flanged-ka ah

Heerka ASME B16.5 wuxuu daboolayaa dhinacyo kala duwan oo ah flanges-ka tuubooyinka iyo qalabka flanged, oo ay ku jiraan qiimeynta heerkulka cadaadiska, agabka, cabbirrada, dulqaadka, calaamadaynta, tijaabinta, iyo qeexidda furitaanka qaybahan. Heerkan waxaa ku jira flanges leh tilmaamo heer qiimayn ah oo u dhexeeya 150 ilaa 2500, oo daboolaya cabbirrada laga bilaabo NPS 1/2 ilaa NPS 24. Waxay bixisaa shuruudaha cutubyada mitirka iyo kuwa Mareykanka labadaba. Waa muhiim in la ogaado in heerkani uu ku kooban yahay flanges-ka iyo qalabka flanged-ka ee laga sameeyay walxaha la shubay ama la been abuuray, oo ay ku jiraan flanges-ka indhoolayaasha ah iyo flanges-ka yareeya ee gaarka ah ee laga sameeyay qalabka la shubay, la been abuuray, ama saxanka.

Wixii flanges tuubooyin ah iyo qalabka flanges-ka ah ee ka weyn 24" NPS, waa in la tixraacaa ASME/ANSI B16.47.

Noocyada Flange-ka Caadiga ah

● Flanges-ka Simbiriirixan: Flanges-kan waxaa badanaa lagu kaydiyaa ANSI Class 150, 300, 600, 1500 & 2500 ilaa 24" NPS. Waxaa "lagu dul simbiriirixan" tuubada ama darafyada ku habboon waxaana lagu dhejiyaa booska, taasoo u oggolaanaysa alxanka fillet-ka gudaha iyo dibadda flange-ka. Noocyada dhimista waxaa loo isticmaalaa in lagu yareeyo cabbirka xariiqda marka boosku xaddidan yahay.

● Flanges-ka Luqunta ee Alxanka: Flanges-kani waxay leeyihiin xuddun dheer oo kala duwan iyo kala-guur siman oo dhumuc ah, taasoo hubinaysa isku-xirka alxanka oo si buuxda u galaya tuubada ama ku-xidhka. Waxaa loo isticmaalaa xaaladaha adeegga ee daran.

● Flanges-ka Kala-goysyada Laabta: Iyadoo lala kaashanayo dhamaadka stub, flanges-ka kala-goysyada dhabta ayaa lagu dul simbiriirixanayaa meesha ku habboon dhamaadka stubka waxaana lagu xiraa alxanka ama siyaabo kale. Naqshadooda dabacsan waxay u oggolaanaysaa isku-dubarid fudud inta lagu jiro isku-dubaridka iyo kala-goynta.

● Flanges-ka Dambe: Flanges-kani ma laha weji kor loo qaaday waxaana loo isticmaalaa giraangiraha dambe, taasoo bixisa xalal kharash-ool ah oo loogu talagalay isku xirka flanges-ka.

● Flanges-ka la duubay (la duubay): Iyada oo caajis ah si ay ula mid noqoto tuubo gaar ah oo dhexroorkeedu yahay gudaha, flanges-ka la duubay waxaa lagu farsameeyaa dun tuubooyin ah oo wareegsan dhinaca dambe, gaar ahaan tuubooyinka godka yar yar.

● Flanges-ka Godka: U eg flanges-ka simbiriirixan, flanges-ka godka godka ayaa lagu farsameeyaa si ay ula jaanqaadaan godadka cabbirka tuubooyinka, taasoo u oggolaanaysa alxanka fillet-ka ee dhinaca dambe si loo sugo isku xirka. Badanaa waxaa loo isticmaalaa tuubooyinka godka yar yar.

● Flanges indho la'aan ah: Flanges-kani ma laha god dhexe waxaana loo isticmaalaa in lagu xiro ama lagu xiro dhammaadka nidaamka tuubooyinka.

Kuwani waa qaar ka mid ah noocyada caadiga ah ee flanges-ka tuubooyinka ee loo isticmaalo codsiyada warshadaha iyo ganacsiga ee kala duwan. Doorashada nooca flanges-ka waxay ku xiran tahay arrimo sida cadaadiska, heerkulka, iyo nooca dareeraha la rarayo, iyo sidoo kale shuruudaha mashruuca gaarka ah. Xulashada saxda ah iyo rakibidda flanges-ka ayaa muhiim u ah hawlgalka badbaadada iyo hufnaanta leh ee nidaamyada tuubooyinka.

Tilmaamaha

| ASME B16.5: Bir Kaarboon, Bir aan Daxal lahayn, Bir Daawaha ah |

| EN 1092-1: Bir Kaarboon, Bir aan Daxal lahayn, Bir Daawaha ah |

| DIN 2501: Bir Kaarboon ah, Bir aan Daxal lahayn, Bir Daxal leh |

| GOST 33259: Bir Kaarboon, Bir aan Daxal lahayn, Bir Daawaha ah |

| SABS 1123: Bir Kaarboon, Bir aan Daxal lahayn, Bir Daawaha ah |

Qalabka Flange-ka

Flanges-ka waxaa lagu dhejiyaa tuubada iyo afka qalabka. Sidaas darteed, waxaa laga sameeyay agabka soo socda;

● Bir kaarboon ah

● Bir daawaha hooseeya

● Bir aan miridh lahayn

● Isku-darka walxaha qalaad (Stub) iyo agabka kale ee taageerada

Liiska agabka loo isticmaalo wax soo saarka waxaa lagu daboolay ASME B16.5 & B16.47.

● ASME B16.5 - Flanges-ka Tuubooyinka iyo Qalabka Flanged-ka ah NPS ½" ilaa 24"

● ASME B16.47 - Dhexroorka Weyn ee Flanges Birta ah NPS 26" ilaa 60"

Qalabka been abuurka ah ee si caadi ah loo isticmaalo waa

● Birta Kaarboonka: – ASTM A105, ASTM A350 LF1/2, ASTM A181

● Birta Daawaha: – ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

● Bir aan miridh lahayn: – ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Cabbirka Flange-ka ee Fasalka 150

| Cabbirka inji | Cabbirka mm | Dia Dibadda. | Flange-ka oo dhumuc weyn leh. | Xarunta OD | Dhererka Flange-ka | RF Dia. | Dhererka RF | PCD | Godka godka | Tirada Bolts | Cabbirka Bolt-ka UNC | Dhererka Boorka Mashiinka | Dhererka Rakaabka RF | Cabbirka Godka | Cabbirka ISO-ga | Miisaanka kg |

|

|

| A | B | C | D | E | F | G | H |

|

|

|

|

|

|

|

| 1/2 | 15 | 90 | 9.6 | 30 | 14 | 34.9 | 2 | 60.3 | 22.2 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.8 |

| 3/4 | 20 | 100 | 11.2 | 38 | 14 | 42.9 | 2 | 69.9 | 27.7 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 49 | 16 | 50.8 | 2 | 79.4 | 34.5 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 19 | 63.5 | 2 | 88.9 | 43.2 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 21 | 73 | 2 | 98.4 | 49.5 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.4 |

| 2 | 50 | 150 | 17.5 | 78 | 24 | 92.1 | 2 | 120.7 | 61.9 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 27 | 104.8 | 2 | 139.7 | 74.6 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 108 | 29 | 127 | 2 | 152.4 | 90.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.7 |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 30 | 139.7 | 2 | 177.8 | 103.4 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5 |

| 4 | 100 | 230 | 22.3 | 135 | 32 | 157.2 | 2 | 190.5 | 116.1 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 5 | 125 | 255 | 22.3 | 164 | 35 | 185.7 | 2 | 215.9 | 143.8 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 6.8 |

| 6 | 150 | 280 | 23.9 | 192 | 38 | 215.9 | 2 | 241.3 | 170.7 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 8.6 |

| 8 | 200 | 345 | 27 | 246 | 43 | 269.9 | 2 | 298.5 | 221.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 13.7 |

| 10 | 250 | 405 | 28.6 | 305 | 48 | 323.8 | 2 | 362 | 276.2 | 12 | 7/8 | 100 | 115 | 1 | M24 | 19.5 |

| 12 | 300 | 485 | 30.2 | 365 | 54 | 381 | 2 | 431.8 | 327 | 12 | 7/8 | 100 | 120 | 1 | M24 | 29 |

| 14 | 350 | 535 | 33.4 | 400 | 56 | 412.8 | 2 | 476.3 | 359.2 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 41 |

| 16 | 400 | 595 | 35 | 457 | 62 | 469.9 | 2 | 539.8 | 410.5 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 54 |

| 18 | 450 | 635 | 38.1 | 505 | 67 | 533.4 | 2 | 577.9 | 461.8 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 59 |

| 20 | 500 | 700 | 41.3 | 559 | 71 | 584.2 | 2 | 635 | 513.1 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 75 |

| 24 | 600 | 815 | 46.1 | 663 | 81 | 692.2 | 2 | 749.3 | 616 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 100 |

Cabbirka Flange-ka Lugta ee Fasalka 150

| Cabbirka inji | Cabbirka mm | Dhexroorka Dibadda | Dhumucda Flange-ka | Xarunta OD | Alxanka Qoorta OD | Dhererka Qoorta Alxanka | Bore | Dhexroorka RF | Dhererka RF | PCD | Wejiga Alxanka |

|

|

| A | B | C | D | E | F | G | H | I | J |

| 1/2 | 15 | 90 | 9.6 | 30 | 21.3 | 46 | Alxanka Qoorta waxaa laga soo qaatay jadwalka tuubada | 34.9 | 2 | 60.3 | 1.6 |

| 3/4 | 20 | 100 | 11.2 | 38 | 26.7 | 51 | 42.9 | 2 | 69.9 | 1.6 | |

| 1 | 25 | 110 | 12.7 | 49 | 33.4 | 54 | 50.8 | 2 | 79.4 | 1.6 | |

| 1 1/4 | 32 | 115 | 14.3 | 59 | 42.2 | 56 | 63.5 | 2 | 88.9 | 1.6 | |

| 1 1/2 | 40 | 125 | 15.9 | 65 | 48.3 | 60 | 73 | 2 | 98.4 | 1.6 | |

| 2 | 50 | 150 | 17.5 | 78 | 60.3 | 62 | 92.1 | 2 | 120.7 | 1.6 | |

| 2 1/2 | 65 | 180 | 20.7 | 90 | 73 | 68 | 104.8 | 2 | 139.7 | 1.6 | |

| 3 | 80 | 190 | 22.3 | 108 | 88.9 | 68 | 127 | 2 | 152.4 | 1.6 | |

| 3 1/2 | 90 | 215 | 22.3 | 122 | 101.6 | 70 | 139.7 | 2 | 177.8 | 1.6 | |

| 4 | 100 | 230 | 22.3 | 135 | 114.3 | 75 | 157.2 | 2 | 190.5 | 1.6 | |

| 5 | 125 | 255 | 22.3 | 164 | 141.3 | 87 | 185.7 | 2 | 215.9 | 1.6 | |

| 6 | 150 | 280 | 23.9 | 192 | 168.3 | 87 | 215.9 | 2 | 241.3 | 1.6 | |

| 8 | 200 | 345 | 27 | 246 | 219.1 | 100 | 269.9 | 2 | 298.5 | 1.6 | |

| 10 | 250 | 405 | 28.6 | 305 | 273 | 100 | 323.8 | 2 | 362 | 1.6 | |

| 12 | 300 | 485 | 30.2 | 365 | 323.8 | 113 | 381 | 2 | 431.8 | 1.6 | |

| 14 | 350 | 535 | 33.4 | 400 | 355.6 | 125 | 412.8 | 2 | 476.3 | 1.6 | |

| 16 | 400 | 595 | 35 | 457 | 406.4 | 125 | 469.9 | 2 | 539.8 | 1.6 | |

| 18 | 450 | 635 | 38.1 | 505 | 457.2 | 138 | 533.4 | 2 | 577.9 | 1.6 | |

| 20 | 500 | 700 | 41.3 | 559 | 508 | 143 | 584.2 | 2 | 635 | 1.6 | |

| 24 | 600 | 815 | 46.1 | 663 | 610 | 151 | 692.2 | 2 | 749.3 | 1.6 |

Cabbirka Flange-ka Indhoolayaasha ah ee Fasalka 150

| Cabbirka | Cabbirka | Dibadda | Flange | RF | RF | PCD | Tirada | Cabbirka Bolt-ka | Bool Mashiin | Raajo RF ah | Cabbirka Godka | ISO Stud | Miisaanka |

| A | B | C | D | E | |||||||||

| 1/2 | 15 | 90 | 9.6 | 34.9 | 2 | 60.3 | 4 | 1/2 | 50 | 55 | 5/8 | M14 | 0.9 |

| 3/4 | 20 | 100 | 11.2 | 42.9 | 2 | 69.9 | 4 | 1/2 | 50 | 65 | 5/8 | M14 | 0.9 |

| 1 | 25 | 110 | 12.7 | 50.8 | 2 | 79.4 | 4 | 1/2 | 55 | 65 | 5/8 | M14 | 0.9 |

| 1 1/4 | 32 | 115 | 14.3 | 63.5 | 2 | 88.9 | 4 | 1/2 | 55 | 70 | 5/8 | M14 | 1.4 |

| 1 1/2 | 40 | 125 | 15.9 | 73 | 2 | 98.4 | 4 | 1/2 | 65 | 70 | 5/8 | M14 | 1.8 |

| 2 | 50 | 150 | 17.5 | 92.1 | 2 | 120.7 | 4 | 5/8 | 70 | 85 | 3/4 | M16 | 2.3 |

| 2 1/2 | 65 | 180 | 20.7 | 104.8 | 2 | 139.7 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 3.2 |

| 3 | 80 | 190 | 22.3 | 127 | 2 | 152.4 | 4 | 5/8 | 75 | 90 | 3/4 | M16 | 4.1 |

| 3 1/2 | 90 | 215 | 22.3 | 139.7 | 2 | 177.8 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 5.9 |

| 4 | 100 | 230 | 22.3 | 157.2 | 2 | 190.5 | 8 | 5/8 | 75 | 90 | 3/4 | M16 | 7.7 |

| 5 | 125 | 255 | 22.3 | 185.7 | 2 | 215.9 | 8 | 3/4 | 85 | 95 | 7/8 | M20 | 9.1 |

| 6 | 150 | 280 | 23.9 | 215.9 | 2 | 241.3 | 8 | 3/4 | 85 | 100 | 7/8 | M20 | 11.8 |

| 8 | 200 | 345 | 27 | 269.9 | 2 | 298.5 | 8 | 3/4 | 90 | 110 | 7/8 | M20 | 20.5 |

| 10 | 250 | 405 | 28.6 | 323.8 | 2 | 362 | 12 | 7/8 | 100 | 115 | 1 | M24 | 32 |

| 12 | 300 | 485 | 30.2 | 381 | 2 | 431.8 | 12 | 7/8 | 100 | 120 | 1 | M24 | 50 |

| 14 | 350 | 535 | 33.4 | 412.8 | 2 | 476.3 | 12 | 1 | 115 | 135 | 1 1/8 | M27 | 64 |

| 16 | 400 | 595 | 35 | 469.9 | 2 | 539.8 | 16 | 1 | 115 | 135 | 1 1/8 | M27 | 82 |

| 18 | 450 | 635 | 38.1 | 533.4 | 2 | 577.9 | 16 | 1 1/8 | 125 | 145 | 1 1/4 | M30 | 100 |

| 20 | 500 | 700 | 41.3 | 584.2 | 2 | 635 | 20 | 1 1/8 | 140 | 160 | 1 1/4 | M30 | 130 |

| 24 | 600 | 815 | 46.1 | 692.2 | 2 | 749.3 | 20 | 1 1/4 | 150 | 170 | 1 3/8 | M33 | 196 |

Heerka & Darajada

| ASME B16.5: Flanges-ka Tuubooyinka iyo Qalabka Flanged-ka ah | Qalabka: Bir Kaarboon, Bir aan Daxal lahayn, Bir Alloy ah |

| EN 1092-1: Flanges-ka iyo kala-goysyadooda - Flanges-ka Wareega ee Tuubooyinka, Walxaha, Qalabka lagu rakibo, iyo Qalabka, PN Loogu talagalay - Qaybta 1: Flanges-ka Birta ah | Qalabka: Bir Kaarboon, Bir aan Daxal lahayn, Bir Alloy ah

|

| DIN 2501: Flanges iyo Kala-goysyada Laabta Ku Jira | Qalabka: Bir Kaarboon, Bir aan Daxal lahayn, Bir Alloy ah |

| GOST 33259: Flanges-ka loogu talagalay Valves-ka, Qalabka lagu rakibo, iyo Tuubooyinka si loogu cadaadiyo PN 250 | Qalabka: Bir Kaarboon, Bir aan Daxal lahayn, Bir Alloy ah |

| SABS 1123: Flanges-ka Tuubooyinka, Qaliimada, iyo Qalabka lagu rakibo | Qalabka: Bir Kaarboon, Bir aan Daxal lahayn, Bir Alloy ah |

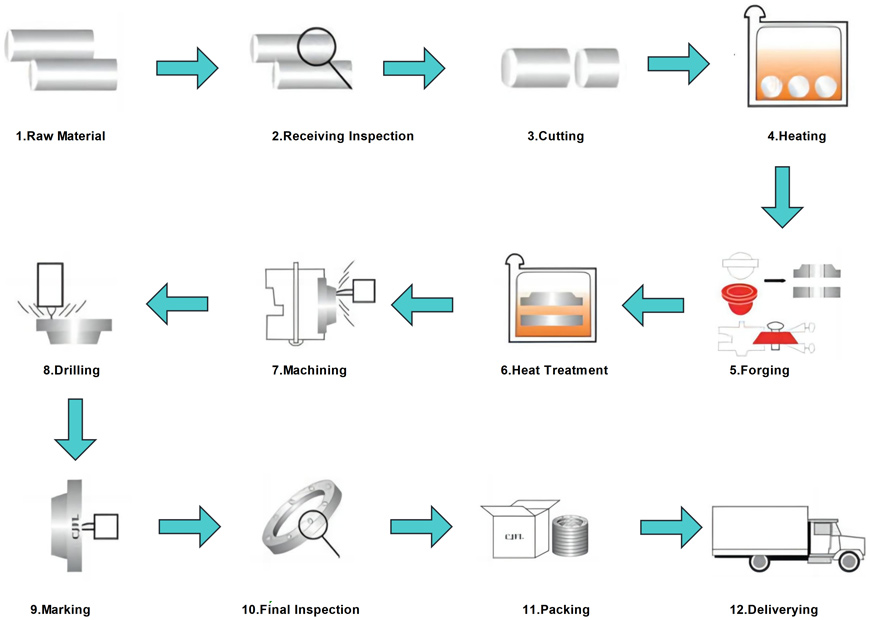

Habka Wax Soo Saarka

Xakamaynta Tayada

Hubinta Walxaha Cayriin, Falanqaynta Kiimikada, Imtixaanka Farsamada, Kormeerka Muuqaalka, Hubinta Cabbirka, Imtixaanka Laabista, Imtixaanka Fidsan, Imtixaanka Saamaynta, Imtixaanka DWT, Baaritaan aan Burburinayn (UT, MT, PT, X-Ray,), Imtixaanka Adkaanta, Tijaabada Cadaadiska, Tijaabada Daadashada Kursiga, Tijaabada Metallography, Tijaabada Daxalka, Tijaabada Iska caabinta Dabka, Tijaabada Buufinta Cusbada, Tijaabada Waxqabadka Socodka, Tijaabada Wareegga iyo Riixista, Rinjiga iyo Kormeerka Dahaarka, Dib u Eegista Dukumentiyada…..

Isticmaalka & Codsiga

Flanges-ku waa qaybo muhiim ah oo warshadeed oo loo isticmaalo in lagu xiro tuubooyinka, waalka, qalabka iyo qaybaha kale ee tuubooyinka. Waxay door muhiim ah ka ciyaaraan isku xirka, taageerada iyo xidhitaanka nidaamyada tuubooyinka. Flanges-ku waxay u adeegaan qaybo muhiim ah codsiyada warshadaha kala duwan, oo ay ku jiraan:

● Nidaamyada Tuubooyinka

● Walxaha

● Qalabka

● Xiriirro

● Shaabadeynta

● Maareynta Cadaadiska

Xirmooyinka iyo Rarista

Womic Steel, waxaan fahamsanahay muhiimadda baakadaha amniga leh iyo raritaan la isku halleyn karo marka ay timaado keenista qalabka tuubooyinka tayo sare leh albaabkaaga. Waa kan dulmar guud oo ku saabsan habraacyadayada baakadaha iyo rarista si aad u tixraacdo:

Baakadaha:

Flanges-ka tuubooyinkayaga si taxaddar leh ayaa loo xirxiray si loo hubiyo inay ku soo gaaraan xaalad qumman, oo diyaar u ah baahiyahaaga warshadaha ama ganacsiga. Hawshayada baakadayntu waxay ka kooban tahay tallaabooyinka muhiimka ah ee soo socda:

● Kormeerka Tayada: Kahor inta aan la xirin, dhammaan flanges-ka waxaa la mariyaa baaritaan tayo oo dhammaystiran si loo xaqiijiyo inay buuxiyeen heerarkayaga adag ee waxqabadka iyo hufnaanta.

● Dahaarka Ilaalinta: Iyada oo ku xidhan nooca agabka iyo codsiga, flanges-keenu waxay heli karaan dahaar ilaalin ah si looga hortago daxalka iyo dhaawaca inta lagu jiro gaadiidka.

● Xirmo Ammaan ah: Flanges-ka si ammaan ah ayaa loogu xidhaa, taasoo hubinaysa inay xasilloon yihiin oo la ilaaliyo inta lagu jiro hawsha rarista.

● Calaamadaynta iyo Dukumentiyada: Baakad kasta waxaa si cad loogu calaamadeeyay macluumaad muhiim ah, oo ay ku jiraan qeexitaannada badeecada, tirada, iyo tilmaamaha gaarka ah ee maaraynta. Dukumentiyada khuseeya, sida shahaadooyinka u hoggaansanaanta, ayaa sidoo kale lagu daray.

● Baakad Gaar ah: Waxaan qaban karnaa codsiyada baakadaha gaarka ah iyadoo lagu saleynayo shuruudahaaga gaarka ah, annagoo hubinayna in flanges-kaaga loo diyaariyey sida loogu baahdo.

Rarista:

Waxaan la shaqeynaa la-hawlgalayaasha maraakiibta sumcadda leh si aan u dammaanad qaadno gaarsiinta la isku halleyn karo oo waqtigeeda ku habboon meesha aad u socoto. Kooxdayada saadka waxay hagaajisaa marinnada maraakiibta si loo yareeyo waqtiyada gaadiidka loona yareeyo khatarta dib u dhaca. Maraakiibta caalamiga ah, waxaan u maareynaa dhammaan dukumentiyada lagama maarmaanka ah ee kastamka iyo u hoggaansanaanta si loo fududeeyo nadiifinta kastamka oo siman. Waxaan bixinaa ikhtiyaarro maraakiib dabacsan, oo ay ku jiraan maraakiib degdeg ah oo loogu talagalay baahiyaha degdegga ah.