Sharaxaadda Badeecada

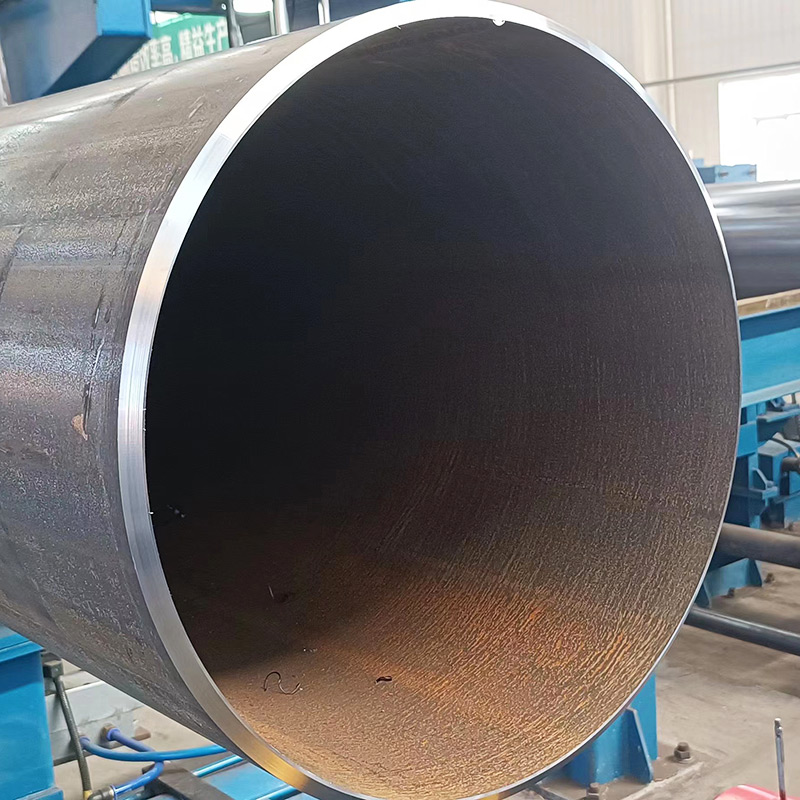

Tuubooyinka birta ah ee LSAW (Longitudinal Submerged Arc Alxanka) waa nooc ka mid ah tuubooyinka birta ah ee la alxanka leh oo lagu garto habka wax soo saarkooda gaarka ah iyo noocyada kala duwan ee codsiyada. Tuubooyinkan waxaa lagu sameeyaa iyadoo la sameeyo saxan bir ah oo qaab dhululubo ah leh oo si dherer leh loogu alxanayo iyadoo la adeegsanayo farsamooyinka alxanka qaansada ee hoos yimaada. Waa kan dulmar guud oo ku saabsan tuubooyinka birta ah ee LSAW:

Habka Wax Soo Saarka:

● Diyaarinta Saxanka: Saxanka birta ee tayada sare leh waxaa lagu xushaa shuruudo gaar ah, taasoo hubinaysa sifooyinka farsamada ee la rabo iyo halabuurka kiimikada.

● Samaynta: Saxanka birta ah waxaa loo qaabeeyey tuubo dhululubo ah iyada oo loo marayo habab sida foorarsiga, rogrogidda, ama riixitaanka (JCOE iyo UOE). Cidhifyada waa la sii qaloociyay si loo fududeeyo alxanka.

● Alxanka: Alxanka qaansada ee biyaha hoostooda ku jira (SAW) ayaa la adeegsadaa, halkaas oo qaansada lagu hayo lakabka qulqulka. Tani waxay soo saartaa alxan tayo sare leh oo leh cillado yar iyo isku-darka aad u fiican.

● Baaritaanka Ultrasonic: Ka dib alxanka, baaritaanka ultrasound-ka ayaa la sameeyaa si loo ogaado cilladaha gudaha ama dibadda ee aagga alxanka.

● Ballaarinta: Tuubada waa la ballaarin karaa si loo gaaro dhexroorka la rabo iyo dhumucda derbiga, taasoo kor u qaadaysa saxnaanta cabbirka.

● Kormeerka Kama Dambeysta ah: Baaritaan dhammaystiran, oo ay ku jiraan kormeerka muuqaalka, hubinta cabbirka, iyo tijaabooyinka hantida farsamada, waxay hubinayaan tayada tuubada.

Faa'iidooyinka:

● Waxtarka Kharashka: Tuubooyinka LSAW waxay bixiyaan xal kharash-ool ah oo loogu talagalay dhuumaha dhexroorka weyn iyo codsiyada qaab-dhismeedka sababtoo ah habka wax-soo-saarka hufan.

● Xoog Sare: Habka alxanka dhererka leh wuxuu keenaa tuubooyin leh sifooyin farsamo oo xooggan oo isku mid ah.

● Saxnaanta Cabbirka: Tuubooyinka LSAW waxay muujiyaan cabbirro sax ah, taasoo ka dhigaysa kuwo ku habboon codsiyada leh dulqaad adag.

● Tayada Alxanka: Alxanka qaansada ee ku dhex jira biyaha ayaa soo saara alxanno tayo sare leh oo leh isku-dhafan aad u fiican iyo cillado yar.

● Kala Duwanaanshaha: Tuubooyinka LSAW waxaa loo isticmaalaa warshado kala duwan, oo ay ku jiraan saliidda iyo gaaska, dhismaha, iyo biyaha, sababtoo ah la qabsigooda iyo cimri dhererkooda.

Marka la soo koobo, tuubooyinka birta ah ee LSAW waxaa lagu sameeyaa iyadoo la adeegsanayo hab sax ah oo hufan, taasoo keentay in la helo tuubooyin badan oo kala duwan, kharash-ool ah, iyo kuwo waara oo ku habboon codsiyo warshadeed oo kala duwan.

Tilmaamaha

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Darajada C250, Darajada C350, Darajada C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

Kala duwanaanshaha wax soo saarka

| Dhexroorka Dibadda | Dhumucda derbiga ee la heli karo oo loogu talagalay heerka birta ka hooseeya | |||||||

| Inji | mm | Heerka Birta | ||||||

| Inji | mm | L245(Gr.B) | L290(X42) | L360(X52) | L415(X60) | L450(X65) | L485(X70) | L555(X80) |

| 16 | 406 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 18 | 457 | 6.0-50.0mm | 6.0-48.0mm | 6.0-48.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 20 | 508 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-40mm | 6.0-31.8mm | 6.0-29.5mm |

| 22 | 559 | 6.0-50.0mm | 6.0-50.0mm | 6.0-50.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 24 | 610 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-45.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 26 | 660 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 28 | 711 | 6.0-57.0mm | 6.0-55.0mm | 6.0-55.0mm | 6.0-48.0mm | 6.0-43mm | 6.0-31.8mm | 6.0-29.5mm |

| 30 | 762 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 32 | 813 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 34 | 864 | 7.0-60.0mm | 7.0-58.0mm | 7.0-58.0mm | 7.0-48.0mm | 7.0-47.0mm | 7.0-35mm | 7.0-32.0mm |

| 36 | 914 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 38 | 965 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 40 | 1016 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 42 | 1067 | 8.0-60.0mm | 8.0-60.0mm | 8.0-60.0mm | 8.0-52.0mm | 8.0-47.0mm | 8.0-35mm | 8.0-32.0mm |

| 44 | 1118 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 46 | 1168 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 48 | 1219 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 52 | 1321 | 9.0-60.0mm | 9.0-60.0mm | 9.0-60.0mm | 9.0-52.0mm | 9.0-47.0mm | 9.0-35mm | 9.0-32.0mm |

| 56 | 1422 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 60 | 1524 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 64 | 1626 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 68 | 1727 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

| 72 | 1829 | 10.0-60.0mm | 10.0-60.0mm | 10.0-60.0mm | 10.0-52mm | 10.0-47.0mm | 10.0-35mm | 10.0-32.0mm |

* Cabbir kale waa la habeyn karaa ka dib gorgortanka

Qaab-dhismeedka Kiimikada iyo Sifooyinka Farsamada ee Tuubada Birta LSAW

| Heerka Caadiga ah | Fasal | Halabuurka Kiimikada (ugu badnaan)% | Sifooyinka Farsamada (daqiiqad) | |||||

| C | Mn | Si | S | P | Xoog Wax-soo-saar (Mpa) | Xoogga Laabista (Mpa) | ||

| GB/T700-2006 | A | 0.22 | 1.4 | 0.35 | 0.050 | 0.045 | 235 | 370 |

| B | 0.2 | 1.4 | 0.35 | 0.045 | 0.045 | 235 | 370 | |

| C | 0.17 | 1.4 | 0.35 | 0.040 | 0.040 | 235 | 370 | |

| D | 0.17 | 1.4 | 0.35 | 0.035 | 0.035 | 235 | 370 | |

| GB/T1591-2009 | A | 0.2 | 1.7 | 0.5 | 0.035 | 0.035 | 345 | 470 |

| B | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| C | 0.2 | 1.7 | 0.5 | 0.030 | 0.030 | 345 | 470 | |

| BS EN10025 | S235JR | 0.17 | 1.4 | - | 0.035 | 0.035 | 235 | 360 |

| S275JR | 0.21 | 1.5 | - | 0.035 | 0.035 | 275 | 410 | |

| S355JR | 0.24 | 1.6 | - | 0.035 | 0.035 | 355 | 470 | |

| DIN 17100 | ST37-2 | 0.2 | - | - | 0.050 | 0.050 | 225 | 340 |

| ST44-2 | 0.21 | - | - | 0.050 | 0.050 | 265 | 410 | |

| ST52-3 | 0.2 | 1.6 | 0.55 | 0.040 | 0.040 | 345 | 490 | |

| JIS G3101 | SS400 | - | - | - | 0.050 | 0.050 | 235 | 400 |

| SS490 | - | - | - | 0.050 | 0.050 | 275 | 490 | |

| API 5L PSL1 | A | 0.22 | 0.9 | - | 0.03 | 0.03 | 210 | 335 |

| B | 0.26 | 1.2 | - | 0.03 | 0.03 | 245 | 415 | |

| X42 | 0.26 | 1.3 | - | 0.03 | 0.03 | 290 | 415 | |

| X46 | 0.26 | 1.4 | - | 0.03 | 0.03 | 320 | 435 | |

| X52 | 0.26 | 1.4 | - | 0.03 | 0.03 | 360 | 460 | |

| X56 | 0.26 | 1.1 | - | 0.03 | 0.03 | 390 | 490 | |

| X60 | 0.26 | 1.4 | - | 0.03 | 0.03 | 415 | 520 | |

| X65 | 0.26 | 1.45 | - | 0.03 | 0.03 | 450 | 535 | |

| X70 | 0.26 | 1.65 | - | 0.03 | 0.03 | 585 | 570 | |

Heerka & Darajada

| Heerka Caadiga ah | Darajooyinka Birta |

| API 5L: Qeexitaanka Tuubada Khadka | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Qeexitaanka Caadiga ah ee Tuubooyinka Birta ee Alxanka leh iyo kuwa aan kala go 'lahayn | GR.1, GR.2, GR.3 |

| EN 10219-1: Qaybaha godan ee qaab-dhismeedka qabow ee alxanka leh ee birta aan dahaarka lahayn iyo kuwa hadhuudhka wanaagsan | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Qaybaha dhismaha ee kulul ee la dhammeeyay ee birta aan birta ahayn iyo kuwa hadhuudhka wanaagsan | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Tuubo, Bir, Madow iyo Kuleyl lagu shubay, Zinc lagu dahaadhay, Alxan leh oo aan sinayn | GR.A, GR.B |

| EN 10208: Tuubooyinka birta ah ee loo isticmaalo nidaamyada gaadiidka dhuumaha ee warshadaha batroolka iyo gaaska dabiiciga ah | L210GA, L235GA, L245GA, L290GA, L360GA |

| EN 10217: Tuubooyinka Birta ah ee la alxamay ee loogu talagalay Ujeeddooyinka Cadaadiska | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Tuubooyinka iyo Tuubooyinka Birta ah ee Laalaaban | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Heerka Australia/New Zealand ee Qaybaha Birta Qaab-dhismeedka Qabow ee Qaab-dhismeedka ah | Darajada C250, Darajada C350, Darajada C450 |

| GB/T 9711: Warshadaha Batroolka iyo Gaaska Dabiiciga ah - Tuubada Birta ah ee Tuubooyinka | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| ASTM A671: Tuubo Bir ah oo Koronto-Fusion-Alxan leh oo loogu talagalay Heerkulka Hawada iyo Heerkulka Hoose | CA 55, CB 60, CB 65, CB 70, CC 60, CC 65, CC 70 |

| ASTM A672: Tuubo bir ah oo koronto ku shaqeeya oo lagu alxamo si loogu adeego cadaadis sare heerkul dhexdhexaad ah. | A45, A50, A55, B60, B65, B70, C55, C60, C65 |

| ASTM A691: Tuubooyinka birta kaarboon iyo kuwa birta ah, oo lagu alxamay isku-darka korantada si loogu adeego cadaadiska sare heerkulka sare. | CM-65, CM-70, CM-75, 1/2CR-1/2MO, 1CR-1/2MO, 2-1/4CR, 3CR |

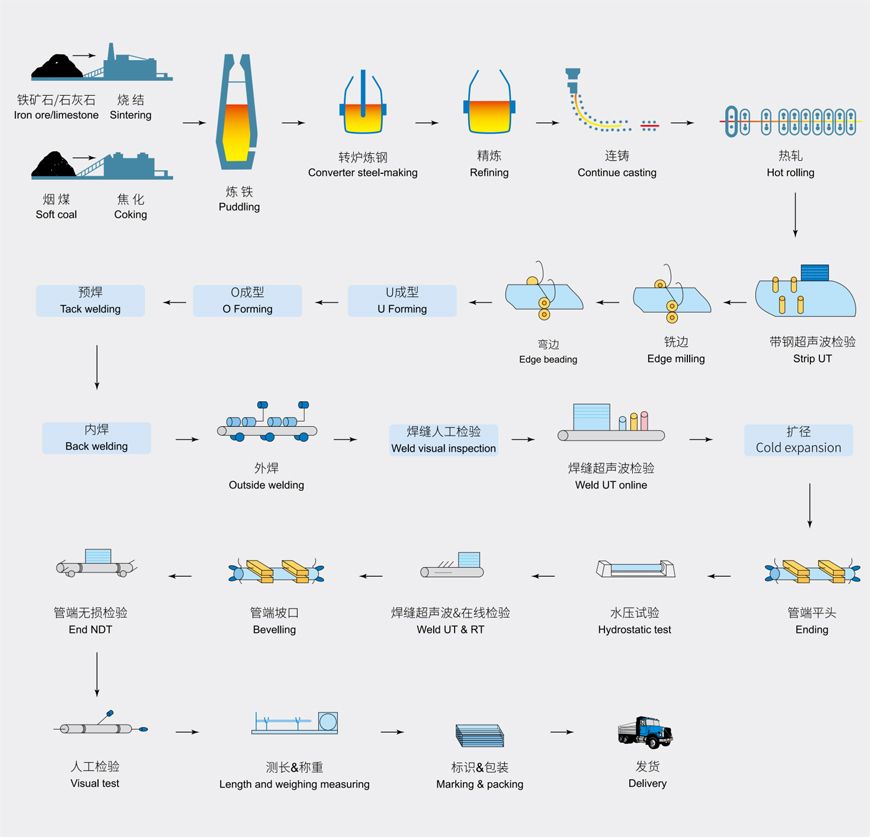

Habka Wax Soo Saarka

Xakamaynta Tayada

● Hubinta Walxaha Cayriin

● Falanqaynta Kiimikada

● Tijaabada Farsamada

● Kormeerka Aragga

● Hubinta Cabbirka

● Tijaabada Laabista

● Tijaabada Saamaynta

● Tijaabada Daxalka ee Isku-dhafka ah

● Baaritaan aan burburin (UT, MT, PT)

● Shahaadada Habka Alxanka

● Falanqaynta Qaab-dhismeedka Yaryar

● Tijaabada Dab-shidka iyo Fiditaanka

● Tijaabada Adkaanta

● Tijaabada Hydrostatic

● Tijaabada Metalografiga

● Tijaabada Dildilaaca Haydarojiin (HIC)

● Tijaabada Dildilaaca Cadaadiska Sulfide (SSC)

● Baaritaanka Hadda ee Eddy

● Kormeerka Rinjiga iyo Dahaarka

● Dib u Eegista Dukumentiyada

Isticmaalka & Codsiga

Tuubooyinka birta ah ee LSAW (Longitudinal Submerged Arc Alxanka) waxay ka helaan codsiyo kala duwan warshado kala duwan sababtoo ah daacadnimadooda qaab-dhismeedka iyo kala duwanaanshahooda. Hoos waxaa ku qoran qaar ka mid ah isticmaalka muhiimka ah iyo codsiyada tuubooyinka birta ah ee LSAW:

● Gaadiidka Saliida iyo Gaaska: Tuubooyinka birta ah ee LSAW waxaa si weyn loogu isticmaalaa warshadaha saliidda iyo gaaska ee nidaamyada dhuumaha. Tuubooyinkan waxaa loo isticmaalaa rarista saliidda cayriin, gaaska dabiiciga ah, iyo dareerayaasha ama gaasaska kale.

● Kaabayaasha Biyaha: Tuubooyinka LSAW waxaa loo isticmaalaa mashaariicda kaabayaasha biyaha la xiriira, oo ay ku jiraan nidaamyada biyaha iyo biyo-mareenka.

● Habaynta Kiimikada: Tuubooyinka LSAW waxay ka shaqeeyaan warshadaha kiimikada halkaas oo loo adeegsado gudbinta kiimikada, dareeraha, iyo gaasaska si ammaan ah oo hufan.

● Dhismaha iyo Kaabayaasha Dhaqaalaha: Tuubooyinkan waxaa loo isticmaalaa mashaariic dhisme oo kala duwan, sida aasaaska dhismaha, buundooyinka, iyo codsiyada kale ee dhismaha.

● Tuurista: Tuubooyinka LSAW waxaa loo adeegsadaa codsiyada tuulista si ay u bixiyaan taageero aasaasi ah mashaariicda dhismaha, oo ay ku jiraan aasaaska dhismaha iyo dhismayaasha badda.

● Qaybta Tamarta: Waxaa loo isticmaalaa in lagu qaado noocyo kala duwan oo tamar ah, oo ay ku jiraan dareerayaasha uumiga iyo kulaylka ee warshadaha korontada dhaliya.

● Macdan qodista: Tuubooyinka LSAW waxay ka helaan codsiyada mashaariicda macdanta ee lagu gudbinayo agabka iyo dabada.

● Habraacyada Warshadaha: Warshadaha sida wax soo saarka iyo wax soo saarka waxay u isticmaalaan tuubooyinka LSAW hababka warshadaha ee kala duwan, oo ay ku jiraan gudbinta alaabta ceeriin iyo alaabada la dhammeeyay.

● Horumarinta Kaabayaasha Dhaqaalaha: Tuubooyinkani waa lama huraan marka la horumarinayo mashaariicda kaabayaasha dhaqaalaha sida waddooyinka, waddooyinka waaweyn, iyo adeegyada dhulka hoostiisa mara.

● Taageerada Dhismaha: Tuubooyinka LSAW waxaa loo isticmaalaa sameynta taageerooyinka dhismaha, tiirarka, iyo alwaaxyada mashaariicda dhismaha iyo injineernimada.

● Dhismaha Maraakiibta: Warshadaha dhismaha maraakiibta, tuubooyinka LSAW waxaa loo isticmaalaa dhismaha qaybo kala duwan oo maraakiibta ah, oo ay ku jiraan qolofka iyo qaybaha dhismaha.

● Warshadaha Gawaarida: Tuubooyinka LSAW waxaa loo isticmaali karaa soo saarista qaybaha baabuurta, oo ay ku jiraan nidaamyada qiiqa.

Codsiyadani waxay muujinayaan kala duwanaanta tuubooyinka birta ah ee LSAW ee qaybaha kala duwan, iyadoo ay ugu wacan tahay cimri dhererkooda, xooggooda, iyo ku habboonaantooda xaaladaha deegaanka ee kala duwan.

Xirmooyinka iyo Rarista

Xirmo habboon iyo rarista tuubooyinka birta ah ee LSAW (Longitudinal Submerged Arc Alxanka) ayaa muhiim u ah hubinta gaadiidkooda iyo gaarsiintooda meela kala duwan. Waa kan sharraxaadda hababka caadiga ah ee xidhmada iyo rarista ee tuubooyinka birta ah ee LSAW:

Baakad:

● Xidhmo: Tuubooyinka LSAW badanaa waa la isku xidhaa ama Hal Qayb ayaa lagu xidhaa iyadoo la adeegsanayo xarig bir ah ama xargo si loo abuuro cutubyo la maarayn karo oo loogu talagalay maaraynta iyo rarista.

● Ilaalinta: Dhamaadka tuubooyinka waxaa lagu ilaaliyaa daboolo balaastig ah si looga hortago waxyeelada inta lagu jiro gaadiidka. Intaa waxaa dheer, tuubooyinka waxaa lagu dabooli karaa walxo ilaalin ah si looga ilaaliyo arrimaha deegaanka.

● Dahaarka Ka-hortagga Daxalka: Haddii tuubooyinku leeyihiin dahaar ka-hortagga daxalka, daacadnimada dahaarka ayaa la hubiyaa inta lagu jiro xidhmada si looga hortago waxyeello inta lagu jiro maaraynta iyo rarista.

● Calaamadaynta iyo Calaamadaynta: Xidhmo kasta waxaa lagu calaamadeeyay macluumaad muhiim ah sida cabbirka tuubada, heerka agabka, lambarka kulaylka, iyo tilmaamo kale si loo fududeeyo aqoonsiga.

● Sugidda: Xirmooyinka waxaa si ammaan ah loogu xiraa baaldiyada ama simbiriirixannada si looga hortago dhaqdhaqaaqa inta lagu jiro rarista.

Rarista:

● Qaababka Gaadiidka: Tuubooyinka birta ah ee LSAW waxaa lagu rari karaa iyadoo la adeegsanayo noocyo kala duwan oo gaadiid ah, oo ay ku jiraan waddo, tareen, badda, ama hawada, iyadoo ku xiran meesha loo socdo iyo degdegga.

● Konteenareynta: Tuubooyinka waxaa lagu rari karaa weelal si loo ilaaliyo, gaar ahaan inta lagu jiro gaadiidka dibadda. Konteenarrada waa la raray oo la sugay si looga hortago in la wareejiyo inta lagu jiro gaadiidka.

● La-hawlgalayaasha Saadka: Shirkadaha sumcadda leh ee saadka ama shirkadaha xamuulka qaada ee khibradda u leh maaraynta tuubooyinka birta ah ayaa la hawlgeliyaa si loo hubiyo in si ammaan ah oo waqtigeeda ah loo keeno.

● Dukumentiyada Kastamka: Dukumentiyada lagama maarmaanka ah ee kastamka, oo ay ku jiraan biilasha rarista, shahaadooyinka asalka ah, iyo waraaqaha kale ee khuseeya, ayaa la diyaariyaa oo loo gudbiyaa shixnadaha caalamiga ah.

● Caymiska: Iyada oo ku xidhan qiimaha iyo nooca xamuulka, caymiska waxaa loo diyaarin karaa si looga hortago dhacdooyinka aan la filayn inta lagu jiro safarka.

● Raad-raaca: Nidaamyada raad-raaca casriga ah waxay u oggolaanayaan diraha iyo qaataha labadaba inay la socdaan horumarka rarista waqtiga dhabta ah, iyagoo hubinaya hufnaan iyo cusbooneysiin waqtigeeda ah.

● Gaarsiinta: Tuubooyinka waxaa laga dejiyaa meesha loo socdo, iyadoo la raacayo habraacyada dejinta saxda ah si looga fogaado waxyeello.

● Kormeerka: Marka la gaaro, tuubooyinka waxaa la mari karaa baaritaan si loo xaqiijiyo xaaladdooda iyo waafaqsanaantooda shuruudaha ka hor inta uusan aqbalin qofka qaadanaya.

Hababka saxda ah ee xirxiridda iyo rarista ayaa ka caawiya ka hortagga burburka, ilaalinta hufnaanta tuubooyinka birta ah ee LSAW, iyo hubinta inay si ammaan ah oo xaalad wanaagsan ku gaaraan meelaha loogu talagalay.