Hordhac:

API 5L waa qeexitaan caadi ah oo uu sameeyay Machadka Batroolka Mareykanka (API) ee tuubooyinka birta ah ee aan kala go 'lahayn iyo kuwa la alxamay ee loo isticmaalo nidaamyada gaadiidka ee warshadaha batroolka iyo gaaska dabiiciga ah. Womic Steel, oo ah soo saaraha hormuudka ka ah tuubooyinka khadka API 5L, waxay bixisaa noocyo badan oo badeecooyin ah oo buuxiya darajooyin iyo tilmaamo kala duwan. Maqaalkani wuxuu bixinayaa isbarbardhig faahfaahsan oo ku saabsan halabuurka kiimikada, sifooyinka farsamada, iyo heerarka tijaabada ee heerarka API 5L ee kala duwan, labadaba PSL1 iyo PSL2 oo ku baahsan saddex nooc oo tuubooyin ah: ERW (Electric Resistance Welded), LSAW (Longitudinal Submerged Arc Welded), iyo SMLS (Seamless).

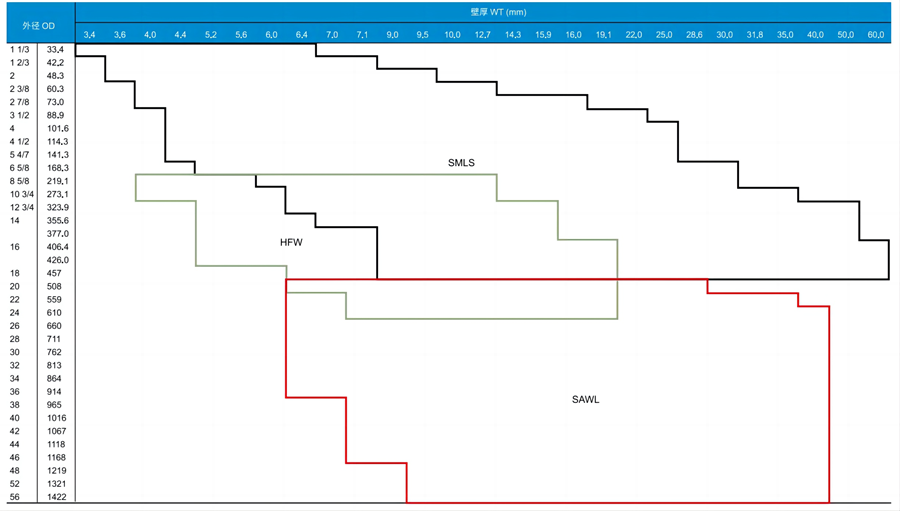

Awoodda Wax Soo Saarka iyo Kala Duwanaanshaha:

| 制造方法 | 钢级起 | 钢级止 | 外径起 OD Ugu yaraan mm | 外径止 | 壁厚起 | 壁厚止 | 生产能力 |

| SMSS | B | X80Q | 33.4 | 457 | 3.4 | 60 | 200000 |

| HFW | B | X80M | 219.1 | 610 | 4.0 | 19.1 | 200000 |

| SAWL | B | X100M | 508 | 1422 | 6.0 | 40 | 500000 |

Dulqaadka Dhexroorka Dibadda

| 标准 | 外径范围 | 外径公差 | 椭圆度 | ||||

| 管体 | 管端 | 管体 | 管端 | ||||

| 无缝 | 焊管 | 无缝 | 焊管 | 无缝 | 焊管 | ||

| API GAAR AH SO 3183 | D <60.3mm | +0.4mm/-0.8mm | +1.6mm/-0.4mm | ||||

| 60.3mm≤D≤168.3mm | +0.75%/-0.75% | ≤2.0% | ≤1.5% | ||||

| 168.3mm | +0.5%/-0.5% | ||||||

| 320mm | +1.6mm/-1.6mm | ||||||

| 426mm | +0.75%/-0.75% | +3.2mm/-3.2mm | |||||

| 610mm | +1.0%/-1.0% | +0.5%/-0.5% | ±2.0mm | ±1.6mm | ≤1.5% | ≤1.0% | |

| 800mm | +4mm/-4mm | ||||||

| 1000mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤1.0% | |||

| 1300mm | +1.0%/-1.0% | +4mm/-4mm | ≤15mm | ≤13mm | |||

Fiiro gaar ah: D waa dhexroorka dibadda ee magacaaban ee tuubada.

Dulqaadka Dhumucda Darbiga

| 标准 | 外径范围 | 壁厚范围 | 壁厚公差 | 壁厚公差 |

| 无缝 | 焊管 | |||

| API GAAR AH ISO 3183 | - | t≤4.0mm | +0.6mm/-0.5mm | +0.5mm/-0.5mm |

| - | 4.0mm | +15%/-12.5% | ||

| - | 5.0mm | +10%/-10% | ||

| - | 15.0mmst <25.0mm | +1.5mm/-1.5mm | ||

| - | 25.0mm≤t <30.0mm | +3.7mm/-3.0mm | ||

| - | 30.0mm≤t <37.0mm | +3.7mm/-10.0% | ||

| - | t≥37.0mm | +10.0%/-10.0% |

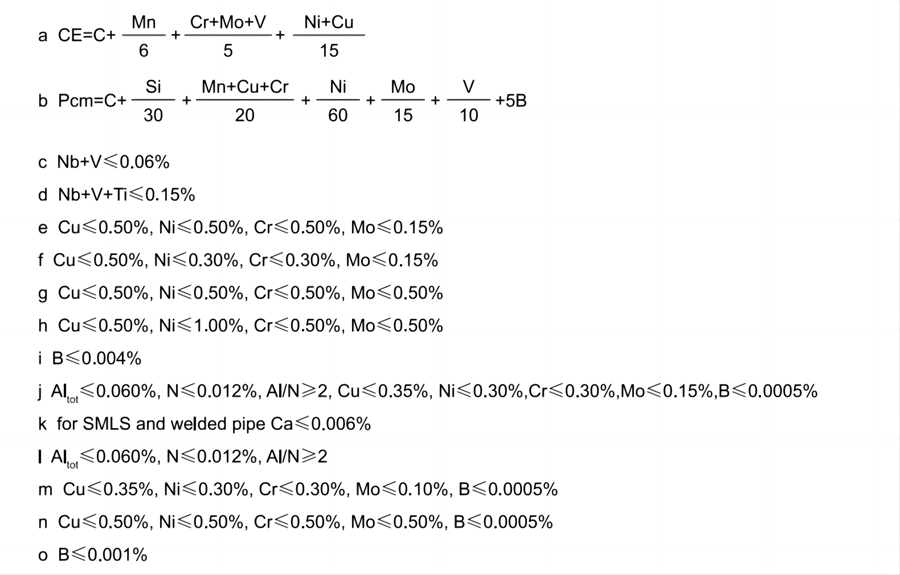

Falanqaynta Kiimikada

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CE | PCm | 备注 |

| ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | |||||

| API SECEM 5L | 无缝管 | PSL1 | L210 ama A | 0.22 |

| 0.90 | 0.030 | 0.030 |

|

|

|

|

| e,o |

| L245 ama B | 0.28 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| c,d,e,o | |||

| L290 ama X42 | 0.28 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L320 ama X46 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 ama X52 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 ama X56 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 ama X60 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 ama X65 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| de,o | |||

| L485 ama X70 | 0.28 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | L245N ama BN | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 |

|

| 0.04 | 0.43 | 0.25 | c,f,o | ||

| L290N ama X42N | 0.24 | 0.40 | 1.20 | 0.025 | 0.015 | 0.06 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320N ama X46N | 0.24 | 0.40 | 1.40 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L360N ama X52N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L390N ama X56N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415N ama X60N | 0.24 | 0.45 | 1.40 | 0.025 | 0.015 | 0.10 | 0.05 | 0.04 | Sida lagu heshiiyay | d,g,o | ||||

| L245Q ama BQ | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L290Q ama X42Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320Q ama X46Q | 0.18 | 0.45 | 1.40 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| 13600 ama × 52Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L390Q ama X56Q | 0.18 | 0.45 | 1.50 | 0.025 | 0.015 | 0.07 | 0.05 | 0.04 | 0.43 | 0.25 | d,f,o | |||

| L415Q ama X60Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450Q ama X65Q | 0.18 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485Q ama X70Q | 0.18 | 0.45 | 1.80 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555Q ama X80Q | 0.18 | 0.45 | 1.90 | 0.025 | 0.015 |

|

|

| Sida lagu heshiiyay | h,i | ||||

| 酸性服 | L245NS ama BNS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 |

|

| 0.04 | 0.36 | 0.22 | c,d,j,k | ||

| L290NS ama X42NS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | j,k | |||

| L320NS ama X46NS | 0.14 | 0.40 | 1.40 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | dj,k | |||

| L360NS ama X52NS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d,j,k | |||

| L245QS ama BQS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L290QS ama X42QS | 0.14 | 0.40 | 1.35 | 0.020 | 0.008 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | j,k | |||

| L320QS ama X46QS | 0.15 | 0.45 | 1.40 | 0.020 | 0.008 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | j,k | |||

| L360QS ama X52QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,j,k | |||

| L390QS ama X56QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,j,k | |||

| L415QS ama X60QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | dj,k | |||

| L450QS ama X65QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| L485QS ama X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.008 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,j,k | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | Ti | CEa | PCm | 备注 |

| ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | |||||

| AP|SPEC 5L | 无缝管 | 海上服 | L245NO ama BNO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 |

|

| 0.04 | 0.36 | 0.22 | c,d, aniga, m |

| L290NO ama X42NO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.22 | l,m | |||

| L320NO ama X46NO | 0.14 | 0.40 | 1.40 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.38 | 0.23 | d, aniga, m | |||

| L360NO ama X52NO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.05 | 0.04 | 0.43 | 0.25 | d, Aniga | |||

| L245QO ama BQO | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L290QO ama X42Q0 | 0.14 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 | 0.34 | 0.22 | l,m | |||

| L320QO ama X46QO | 0.15 | 0.45 | 1.40 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 | 0.36 | 0.23 | l,m | |||

| L360QO ama X52QO | 0.16 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.39 | 0.23 | d,I,n | |||

| L390QO ama X56Q0 | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.07 | 0.05 | 0.04 | 0.40 | 0.24 | d,I,n | |||

| L415QO ama X60QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.05 | 0.04 | 0.41 | 0.25 | d,I,n | |||

| L455QO ama X65QO | 0.15 | 0.45 | 1.65 | 0.020 | 0.010 | 0.09 | 0.05 | 0.06 | 0.42 | 0.25 | d,I,n | |||

| L485Q0 ama X70Q0 | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | 0.42 | 0.25 | d,l,n | |||

| L555QO ama X80QO | 0.17 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.06 | 0.06 | Sida lagu heshiiyay | d,I,n | ||||

| 焊管 | PSL1 | L245 ama B | 0.26 |

| 1.20 | 0.030 | 0.030 |

|

|

|

|

| cd,e,c | |

| L290 amaX42 | 0.26 |

| 1.30 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L320 amaX46 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L360 ama X52 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L390 amaX56 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L415 amaX60 | 0.26 |

| 1.40 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L450 ama X65 | 0.26 |

| 1.45 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| L485 ama X70 | 0.26 |

| 1.65 | 0.030 | 0.030 |

|

|

|

|

| d,e,o | |||

| PSL2 | 1245M ama BM | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | ||

| L290M ama X42M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L320M ama X46M | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 0.05 | 0.05 | 0.04 | 0.43 | 0.25 | f,o | |||

| L360M ama X52M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L390M ama X56M | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,f,o | |||

| L415M ama X60M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L450M ama X65M | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L485M ama X70M | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| L555M ama X80M | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 |

|

|

| 0.43 | 0.25 | d,g,o | |||

| 标准 | 钢管种类 | 等级 | 钢级 | C | Si | Mn | P | S | V | Nb | T | CEa | PCm | 备注 |

| ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | ugu badan | |||||

| API SECEM 5L | 焊管 | 酸性服 | L245MS ama BMS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k |

| L290MS ama X42MS | 0.10 | 0.40 | 1.25 | 0.020 | 0.002 | 0.04 | 0.04 | 0.04 |

| 0.19 | j,k | |||

| L320MS ama X46MS | 0.10 | 0.45 | 1.35 | 0.020 | 0.002 | 0.05 | 0.05 | 0.04 |

| 0.20 | j,k | |||

| L360MS ama X52MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.05 | 0.06 | 0.04 |

| 0.20 | j,k | |||

| L390MS ama X56MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,j,k | |||

| L415MS ama X60MS | 0.10 | 0.45 | 1.45 | 0.020 | 0.002 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,j,k | |||

| L450MS ama X65MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,j,k | |||

| L485MS ama X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 | 0.10 | 0.08 | 0.06 |

| 0.22 | dj,k | |||

| 海上服 | L245MO ama BMO | 0.12 | 0.40 | 1.25 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | ||

| L290MO ama X42MO | 0.12 | 0.40 | 1.35 | 0.020 | 0.010 | 0.04 | 0.04 | 0.04 |

| 0.19 | l,m | |||

| L320MO ama X46MO | 0.12 | 0.45 | 1.35 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | Aniga, aniga | |||

| L360MO ama X52MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.05 | 0.05 | 0.04 |

| 0.20 | d,I,n | |||

| L390MO ama X56MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.06 | 0.08 | 0.04 |

| 0.21 | d,l,n | |||

| L415MO ama X60MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.08 | 0.08 | 0.06 |

| 0.21 | d,I,n | |||

| L450MO ama X65MO | 0.12 | 0.45 | 1.65 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.222 | d,I,n | |||

| L485MO ama X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.22 | d,l,n | |||

| L555MO ama X80MO | 0.12 | 0.45 | 1.85 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 |

| 0.24 | d,I,n |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SECEM 5L | PSL1 | L210 ama A | Ugu yaraan | 210 | 335 | a |

| 335 |

| L245 ama B | Ugu yaraan | 245 | 415 | a |

| 415 | ||

| L290 ama X42 | Ugu yaraan | 290 | 415 | a |

| 415 | ||

| L320 ama X46 | Ugu yaraan | 320 | 435 | a |

| 435 | ||

| L360 ama X52 | Ugu yaraan | 360 | 460 | a |

| 460 | ||

| L390 ama X56 | Ugu yaraan | 390 | 490 | a |

| 490 | ||

| L415 ama X60 | Ugu yaraan | 415 | 520 | a |

| 520 | ||

| L450 ama X65 | Ugu yaraan | 450 | 535 | a |

| 535 | ||

| L485 ama X70 | Ugu yaraan | 485 | 570 | a |

| 570 | ||

| PSL2 | L245N ama BN | Ugu yaraan | 245 | 415 | a |

| 415 | |

| Ugu badnaan | 450 | 655 |

| 0.93 |

| |||

| L290N ama X42N | Ugu yaraan | 290 | 415 | a |

| 415 | ||

| Ugu badnaan | 495 | 655 |

| 0.93 |

| |||

| L320N ama X46N | Ugu yaraan | 320 | 435 | a |

| 435 | ||

| Ugu badnaan | 525 | 655 |

| 0.93 |

| |||

| L360N ama X52N | Ugu yaraan | 360 | 460 | a |

| 460 | ||

| Ugu badnaan | 530 | 760 |

| 0.93 |

| |||

| L390N ama X56N | Ugu yaraan | 390 | 490 | a |

| 490 | ||

| Ugu badnaan | 545 | 760 |

| 0.93 |

| |||

| L415N ama X60N | Ugu yaraan | 415 | 520 | a |

| 520 | ||

| Ugu badnaan | 565 | 760 |

| 0.93 |

| |||

| L450Q ama X65Q | Ugu yaraan | 450 | 535 | a |

| 535 | ||

| Ugu badnaan | 600 | 760 |

| 0.93 |

| |||

| L485Q ama X70Q | Ugu yaraan | 485 | 570 | a |

| 570 | ||

| Ugu badnaan | 635 | 760 |

| 0.93 |

| |||

| L555Q ama X80Q | Ugu yaraan | 555 | 625 | a |

| 625 | ||

| Ugu badnaan | 705 | 825 |

| 0.93 |

| |||

| L625M ama X90M | Ugu yaraan | 625 | 695 | a |

| 695 | ||

| Ugu badnaan | 775 | 915 |

| 0.95 |

| |||

| L690M ama X100M | Ugu yaraan | 690 | 760 | a |

| 760 | ||

| Ugu badnaan | 840 | 990 |

| 0.97 |

| |||

| L830M ama X120M | Ugu yaraan | 830 | 915 | a |

| 915 | ||

| Ugu badnaan | 1050 | 1145 |

| 0.99 |

| 标准 | 等级 | 钢级 |

| 屈服强度 | 抗拉强度 | 延伸率 | 屈强比 | 焊缝抗拉强度 |

| API SECEM 5L | 酸性服 | L245NS ama BNS | Ugu yaraan | 245 | 415 | a |

| 415 |

| Ugu badnaan | 450 | 655 |

| 0.93 |

| |||

| L290NS ama X42NS | Ugu yaraan | 290 | 415 | a |

| 415 | ||

| Ugu badnaan | 495 | 655 |

| 0.93 |

| |||

| L320NS ama X46NS | Ugu yaraan | 320 | 435 | a |

| 435 | ||

| Ugu badnaan | 525 | 655 |

| 0.93 |

| |||

| L360NS ama X52NS | Ugu yaraan | 360 | 460 | a |

| 460 | ||

| Ugu badnaan | 530 | 760 |

| 0.93 |

| |||

| L390QS ama X56QS | Ugu yaraan | 390 | 490 | a |

| 490 | ||

| Ugu badnaan | 545 | 760 |

| 0.93 |

| |||

| L415QS ama X60QS | Ugu yaraan | 415 | 520 | a |

| 520 | ||

| Ugu badnaan | 565 | 760 |

| 0.93 |

| |||

| L450QS ama X65QS | Ugu yaraan | 450 | 535 | a |

| 535 | ||

| Ugu badnaan | 600 | 760 |

| 0.93 |

| |||

| L485QS ama X70QS | Ugu yaraan | 485 | 570 | a |

| 570 | ||

| Ugu badnaan | 635 | 760 |

| 0.93 |

| |||

| 海上服 | L245NO ama BNO | Ugu yaraan | 245 | 415 | a | - | 415 | |

| Ugu badnaan | 450 | 655 |

| 0.93 |

| |||

| L290NO ama X42NO | Ugu yaraan | 290 | 415 | a |

| 415 | ||

| Ugu badnaan | 495 | 655 |

| 0.93 |

| |||

| L320NO ama X46NO | Ugu yaraan | 320 | 435 | a |

| 435 | ||

| Ugu badnaan | 520 | 655 |

| 0.93 |

| |||

| L360NO ama X52NO | Ugu yaraan | 360 | 460 | a |

| 460 | ||

| Ugu badnaan | 525 | 760 |

| 0.93 |

| |||

| L390QO ama X56QO | Ugu yaraan | 390 | 490 | a |

| 490 | ||

| Ugu badnaan | 540 | 760 |

| 0.93 |

| |||

| L415QO ama X60QO | Ugu yaraan | 415 | 520 | a | - | 520 | ||

| Ugu badnaan | 565 | 760 |

| 0.93 |

| |||

| L450QO ama X65QO | Ugu yaraan | 450 | 535 | a | - | 535 | ||

| Ugu badnaan | 570 | 760 |

| 0.93 |

| |||

| L485Q0 ama X70Q0 | Ugu yaraan | 485 | 570 | a |

| 570 | ||

| Ugu badnaan | 605 | 760 |

| 0.93 |

| |||

| L555QO ama X80QO | Ugu yaraan | 555 | 625 | a |

| 625 | ||

| Ugu badnaan | 675 | 825 |

| 0.93 |

Fiiro gaar ah: a: Kordhinta ugu yar iyadoo la isticmaalayo isle'egta soo socota: A1=1940*A0.2/U0.9

| 钢级 | 管体最小横向冲击功(1(2)(3) | 焊缝最小横向冲击功(1(2(3) | |||||

| D≤508 | 508mm | 762mm | 914mm | 1219mm | D <1422mm | D=1422mm | |

| ≤L415 ama X60 | 27(20) | 27(20) | 40 (30) | 40 (30) | 40 (30) | 27(20) | 40 (30) |

| > L415 ama X60 | 27(20) | 27(20) | 40 (30) | 40 (30) | 54 (40) | 27(20) | 40 (30) |

| > L450 ama X65 | 27(20) | 27(20) | 40 (30) | 40 (30) | 54 (40) | 27(20) | 40 (30) |

| >L485 ama X70 | 40 (30) | 40 (30) | 40 (30) | 40 (30) | 54 (40) | 27(20) | 40 (30) |

Fiiro gaar ah: (1) Qiimaha jadwalka ku jira waxay ku habboon yihiin muunadda caadiga ah ee cabbirka buuxa.

(2) Qiimaha ku jira qaybta hoose waa qiimaha ugu yar ee hal-hal ah, qaybta dibadda waa qiimaha celceliska.

(3) Heerkulka Tijaabada: 0°C.

Heerarka Imtixaanka:

Tuubooyinka API 5L ee khadka ah ee ay soo saarto Womic Steel ayaa mara tijaabooyin adag si loo hubiyo inay buuxiyaan heerarka tayada ugu sarreeya. Heerarka tijaabada waxaa ka mid ah:

Falanqaynta Kiimikada:

Halabuurka kiimikada ee birta ayaa la falanqeeyaa si loo xaqiijiyo inuu buuxiyo shuruudaha qeexitaanka API 5L.

Falanqaynta kiimikada waxaa lagu sameeyaa iyadoo la adeegsanayo qalab si toos ah loo akhriyo si loo go'aamiyo halabuurka curiyaha birta.

Tijaabada Farsamada:

Sifooyinka farsamada sida xoogga wax soo saarka, xoogga jiidista, iyo dheereynta ayaa la tijaabiyaa si loo hubiyo inay buuxiyaan shuruudaha la cayimay.

Tijaabada farsamada waxaa lagu sameeyaa iyadoo la adeegsanayo mashiinka tijaabada ah ee 60-tan si loo cabbiro xoogga iyo dabacsanaanta birta.

Tijaabada Hydrostatic:

Tijaabada Hydrostatic-ka ayaa la sameeyaa si loo hubiyo hufnaanta tuubada loona hubiyo inay u adkeysan karto shuruudaha cadaadiska ee loo adeegsaday.

Tuubooyinka waxaa ka buuxa biyo waxaana la mariyaa cadaadis, iyadoo muddada tijaabada iyo heerarka cadaadiska ay qeexayaan heerarka API 5L.

Tijaabada Aan Wax Burburinayn (NDT):

Hababka NDT sida baaritaanka ultrasonic (UT) iyo baaritaanka walxaha birlabta (MT) ayaa loo isticmaalaa in lagu ogaado cilladaha ama kala go'a tuubada.

UT waxaa loo isticmaalaa in lagu aqoonsado cilladaha gudaha, halka MT loo isticmaalo in lagu ogaado cilladaha dusha sare.

Tijaabada Saamaynta:

Tijaabada saameynta ayaa la sameeyaa si loo qiimeeyo adkaanta birta heerkul hooseeya.

Tijaabada saameynta Charpy waxaa badanaa loo isticmaalaa in lagu cabbiro tamarta saameynta ee birta nuugta.

Tijaabada Adkaanta:

Tijaabada adkaanta ayaa la sameeyaa si loo qiimeeyo adkaanta birta, taasoo muujin karta xooggeeda iyo ku habboonaanteeda codsiyada gaarka ah.

Tijaabada adag ee Rockwell waxaa badanaa loo isticmaalaa in lagu cabbiro adkaanta birta.

Baaritaanka Qaab-dhismeedka Yar:

Baaritaanka qaab-dhismeedka yar-yar ayaa la sameeyaa si loo qiimeeyo qaab-dhismeedka hadhuudhka iyo tayada guud ee birta.

Microscope-ka birta ayaa loo isticmaalaa in lagu baaro qaab-dhismeedka birta iyo in la aqoonsado wax kasta oo aan caadi ahayn.

Iyadoo raacaysa heerarkan tijaabada ah ee adag, Womic Steel waxay hubineysaa in tuubooyinka API 5L ee khadka ah ay buuxiyaan shuruudaha tayada ugu sarreeya waxayna bixiyaan waxqabad la isku halleyn karo oo ku saabsan codsiyada warshadaha kala duwan.

Habka Wax Soo Saarka:

1. Tuubooyinka Birta ah ee aan kala go 'lahayn:

- Xulashada Walxaha Cayriin: Billets bir wareegsan oo tayo sare leh ayaa loo xushay soo saarista tuubooyin bir ah oo aan kala go 'lahayn.

- Kuleylinta iyo Daloolista: Billet-yada waxaa lagu kululeeyaa heerkul sare ka dibna waxaa la dalooliyaa si loo sameeyo qolof godan.

- Rogidda iyo Cabbirka: Qolofka la dalooliyay ayaa markaa la rogaa oo la fidiyaa dhexroorka iyo dhumucda la rabo.

- Daaweynta Kulaylka: Tuubooyinka waxaa lagu sameeyaa hababka daaweynta kulaylka sida baabi'inta ama caadiyaynta si loo hagaajiyo sifooyinkooda farsamada.

- Dhammaystirka: Tuubooyinka waxaa la mariyaa hababka dhammaystirka sida toosinta, jarista, iyo kormeerka.

- Tijaabinta: Tuubooyinka waxay maraan baaritaanno kala duwan, oo ay ku jiraan baaritaanka hydrostatic, baaritaanka ultrasound, iyo baaritaanka hadda jira ee eddy, si loo hubiyo tayadooda.

- Daawaynta Dusha Sare: Tuubooyinka waxaa lagu dahaadhi karaa ama lagu daweyn karaa si looga hortago miridhku oo loo hagaajiyo muuqaalkooda.

- Baakadaha iyo Rarista: Tuubooyinka si taxaddar leh ayaa loo xirxiraa oo loo geeyaa macaamiisha.

2. Dhuumaha Birta ah ee LSAW (Alxanka Qaanso ee Dhexroorka Dheer):

- Diyaarinta Saxanka: Saxanka birta tayo sare leh ayaa loo diyaariyaa soo saarista tuubooyinka LSAW.

- Samaynta: Saxannada waxaa loo sameeyaa qaab "U" iyadoo la isticmaalayo mashiin horay loo foorariyay.

- Alxanka: Taarikada qaabka "U" ayaa markaa la isku dhejiyaa iyadoo la adeegsanayo habka alxanka qaansada ee biyaha hoostooda ku jira.

- Ballaarinta: Tolmada la alxamay waxaa lagu fidiyaa dhexroorka la rabo iyadoo la isticmaalayo mashiin balaadhinaya gudaha ama dibadda.

- Kormeerka: Tuubooyinka waxaa lagu sameeyaa baaritaan si loo ogaado cilladaha iyo saxnaanta cabbirka.

- Tijaabada Ultrasonic: Tuubooyinka waxaa lagu sameeyaa baaritaan ultrasound ah si loo ogaado cilladaha gudaha.

- Qeexid: Dhammaadka tuubooyinka waxaa loo sameeyay qaab alxan ah.

- Dahaarka iyo Calaamadaynta: Tuubooyinka waxaa lagu dahaadhi karaa oo lagu calaamadayn karaa iyadoo loo eegayo shuruudaha macaamiisha.

- Baakadaha iyo Rarista: Tuubooyinka waa la baakadeeyaa oo loo raraa macaamiisha.

3. Tuubooyinka Birta ee HFW (Alxanka Soo Noqnoqda Sare):

- Diyaarinta Gariiradda: Gariiradda birta ah waxaa loo diyaariyaa soo saarista tuubooyinka HFW.

- Samaynta iyo Alxanka: Xargaha waxaa loo sameeyaa qaab dhululubo ah ka dibna waxaa lagu alxanayaa iyadoo la isticmaalayo alxanka soo noqnoqda sare leh.

- Kuleylinta Tolmada Alxanka: Tolmada alxanka waxaa lagu kululeeyaa heerkulka alxanka iyadoo la adeegsanayo kuleylinta soo noqnoqoshada sare leh.

- Cabbirka: Tuubada la alxamay waxaa lagu cabbiraa dhexroorka iyo dhumucda loo baahan yahay.

- Jarida iyo Qallajinta: Tuubada waxaa loo gooyaa dhererka la rabo, darafyaduna waa la jarjaray si loo alxamo.

- Kormeerka: Tuubooyinka waxaa lagu sameeyaa baaritaan si loo ogaado cilladaha iyo saxnaanta cabbirka.

- Tijaabada Hydrostatic: Tuubooyinka waxaa lagu tijaabiyaa xoog iyo daadasho iyadoo la adeegsanayo tijaabada hydrostatic.

- Dahaarka iyo Calaamadaynta: Tuubooyinka waxaa lagu dahaadhay oo lagu calaamadeeyay iyadoo loo eegayo shuruudaha macaamiisha.

- Baakadaha iyo Rarista: Tuubooyinka waa la baakadeeyaa oo loo raraa macaamiisha.

Hababkan wax soo saarka ee faahfaahsan waxay hubinayaan tayada sare iyo isku halaynta tuubooyinka birta ah ee LSAW, iyo HFW ee ay soo saarto Womic Steel, iyagoo buuxinaya shuruudaha adag ee warshadaha kala duwan.

Daaweynta Dusha Sare:

Daaweynta dusha sare ee birta dhuumaha ayaa muhiim u ah hagaajinta iska caabbinta daxalka iyo cimriga adeegga. Womic Steel waxay isticmaashaa habab kala duwan oo lagu daweeyo dusha sare iyadoo ku xiran shuruudaha kala duwan ee macaamiisha, oo ay ku jiraan:

1. Galvanization-ka kulul: Tuubada birta ah waxaa lagu dhex geliyaa zinc dhalaalay si loo sameeyo lakab ilaalin ah oo bir ah oo zinc-bir ah, taasoo kor u qaadaysa iska caabbinta daxalka. Galvanization-ka kulul wuxuu ku habboon yahay dhuumaha caadiga ah iyo kuwa cadaadiska hooseeya.

2. Dahaarka ka hortagga daxalka: Dahaarka caadiga ah ee ka hortagga daxalka waxaa ka mid ah dahaarka epoxy, dahaarka polyethylene, iyo dahaarka polyurethane. Dahaarkani wuxuu si wax ku ool ah uga hortagaa oksaydhka iyo daxalka dusha sare ee tuubada birta ah, taasoo sii dheereyneysa cimrigeeda shaqada.

3. Barafeynta Ciidda: Barafeynta xawaaraha sare leh waxaa loo isticmaalaa in lagu nadiifiyo tuubada birta ah, iyadoo laga saarayo miridhku iyo wasakhda dusha sare, taasoo siineysa aasaas wanaagsan oo loogu talagalay daawaynta dahaarka ee dambe.

4. Daawaynta Dahaarka: Dusha sare ee tuubada birta ah waxaa lagu dahaadhi karaa rinji ka hortagga daxalka, rinjiyada laamiga ah, iyo dahaadh kale si loo xoojiyo iska caabbinta daxalka, oo ku habboon dhuumaha dhulka hoostiisa mara iyo dhuumaha ee deegaannada badda.

Hababkaan daaweynta dusha sare si wax ku ool ah ayay birta dhuumaha uga ilaaliyaan daxalka iyo dhaawaca, iyagoo hubinaya isku hallaynteeda iyo cimri dhererkeeda deegaanno kala duwan oo adag.

Baakadaha iyo Gaadiidka:

Womic Steel waxay xaqiijisaa baakadaha badbaadada leh iyo gaadiid la isku halleyn karo oo birta dhuumaha ah, iyadoo bixinaysa fursado dabacsan si loo daboolo baahiyaha macaamiisha kala duwan:

1. Xamuul Badan: Dalabyada waaweyn, birta dhuumaha waxaa lagu rari karaa si weyn iyadoo la adeegsanayo xamuul gaar ah. Birta waxaa si toos ah loogu shubaa meesha markabka la dhigo iyada oo aan la isticmaalin baakad, taasoo ku habboon gaadiid kharash-ool ah oo tiro badan.

2. LCL (Ka Yar Rarka Weelka): Dalabyada yaryar, birta dhuumaha waxaa loo rari karaa sidii xamuul LCL ah, halkaas oo dalabyo badan oo yaryar lagu daro hal weel. Habkani waa mid kharash-ool ah oo loogu talagalay tiro yar wuxuuna bixiyaa jadwal gaarsiin oo dabacsan.

3. FCL (Konteenar Buuxa): Macaamiishu waxay dooran karaan rarida FCL, halkaas oo weel buuxa loogu talagalay dalabkooda. Habkani wuxuu bixiyaa waqtiyo safar oo dhakhso badan wuxuuna yareeyaa khatarta waxyeelada inta lagu jiro maaraynta.

4. Xamuulka Hawada: Dalabyada degdegga ah, Xamuulka hawada ayaa diyaar u ah keenista degdega ah. In kasta oo ay ka qaalisan tahay Xamuulka badda, haddana Xamuulka hawada wuxuu bixiyaa gaadiid degdeg ah oo la isku halleyn karo oo loogu talagalay shixnadaha xasaasiga ah waqtiga.

Womic Steel waxay hubisaa in dhammaan shixnadaha si ammaan ah loogu xidho baakado si looga hortago burburka inta lagu jiro rarista. Birta waxaa badanaa lagu duubaa agab ilaalin ah waxaana lagu xidhaa weelal ama baaldiyo si loo hubiyo xasilloonida inta lagu jiro rarista. Intaa waxaa dheer, shirkaddu waxay si dhow ula shaqaysaa la-hawlgalayaasha maraakiibta sumcadda leh si loo hubiyo keenista waqtiga ku habboon iyo maaraynta saadka oo hufan.

Xaaladaha Codsiga:

Tuubooyinka API 5L ee khadka ah ee ay soo saarto Womic Steel ayaa si weyn loogu isticmaalaa warshadaha batroolka iyo gaaska dabiiciga ah si loogu raro saliidda, gaaska, iyo dareerayaasha kale. Waxaa sidoo kale loo isticmaalaa warshado kale oo kala duwan sida farsamaynta kiimikada, soo saarista korontada, iyo dhismaha.

Gunaanad:

Womic Steel waa shirkad lagu kalsoon yahay oo soo saarta tuubooyinka API 5L, waxayna bixisaa alaab tayo sare leh oo buuxisa shuruudaha adag ee warshadaha batroolka iyo gaaska dabiiciga ah. Iyadoo diiradda la saarayo tayada, isku halaynta, iyo qanacsanaanta macaamiisha, Womic Steel waxay sii ahaanaysaa doorasho ay doorbidaan macaamiisha adduunka oo dhan.

Waqtiga boostada: Maarso-22-2024