ASTM A182 Flanges-ka Birta ah ee la been abuuray ama la duubay, Qalabka la been abuuray, iyo Valves-yada

ASTM A182 waa qeexitaan muhiim ah oo loogu talagalay flanges-ka birta ah ee la been abuuray ama la duubay, qalabka la been abuuray, iyo waalka loogu talagalay in loogu isticmaalo jawi heerkul sare leh oo cadaadis sare leh. Heerkani wuxuu bixiyaa tilmaamo ku saabsan halabuurka kiimikada, sifooyinka farsamada, hababka tijaabada, iyo arrimo kale oo muhiim ah oo hubiya cimriga iyo isku halaynta qaybahan codsiyada muhiimka ah.

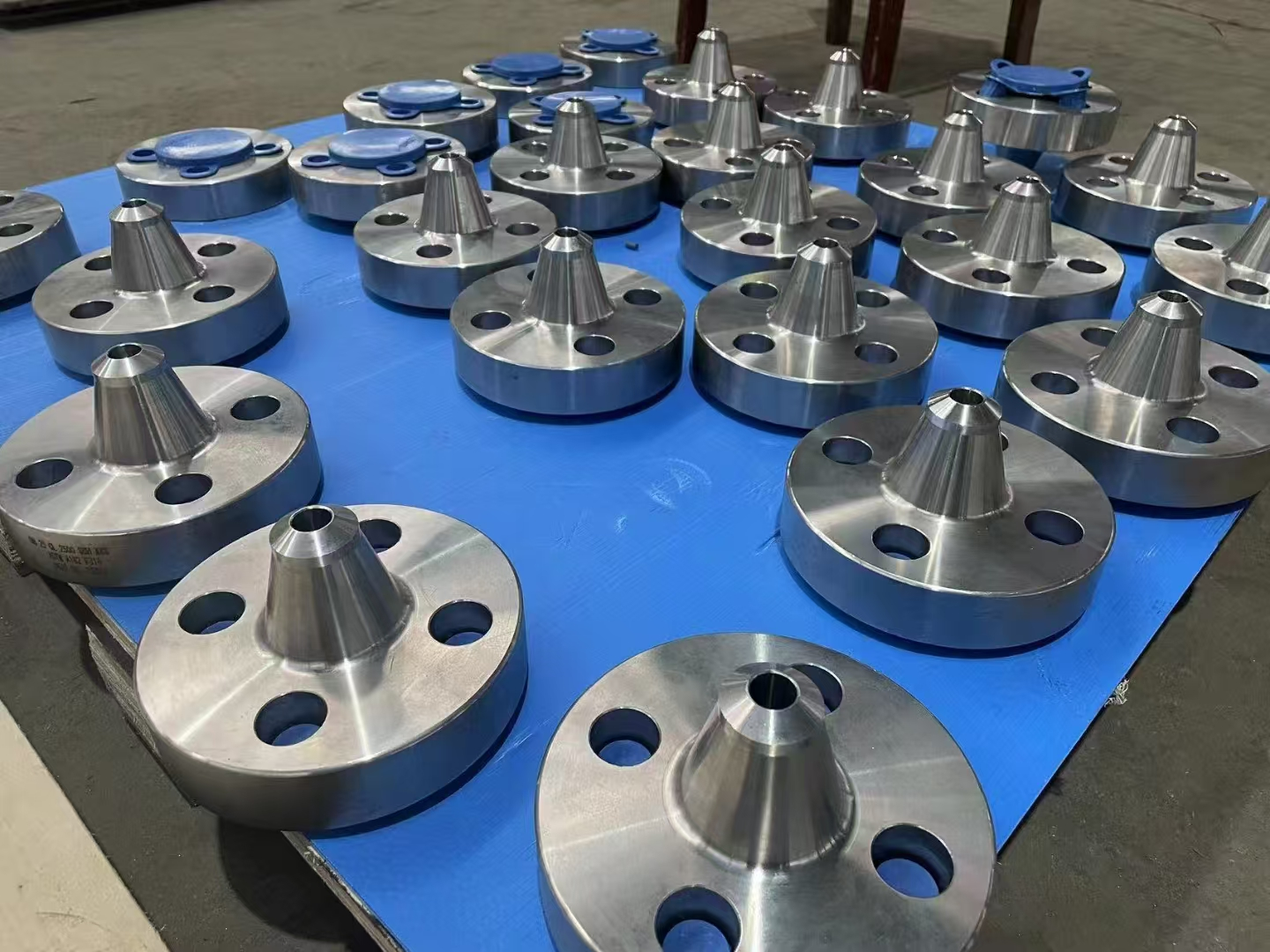

Womic Steel, waxaan soo saarnaa noocyo badan oo badeecooyin ah oo u hoggaansan heerka ASTM A182, iyagoo bixinaya tayo sare iyo saxnaan. Maqaalkan, waxaan ku sahamin doonnaa qodobbada muhiimka ah ee heerkan waxaanan ku soo bandhigi doonnaa awoodaha wax soo saarka ee Womic Steel iyo faa'iidooyinka ay leedahay inaad naga doorato alaab-qeybiyahaaga.

Noocyada Badeecadaha ay daboolayso ASTM A182

ASTM A182 waxay daboolaysaa qaybo kala duwan oo bir ah oo la been abuuray ama la duubay, oo ay ku jiraan:

1. Flanges - Kuwaas waxaa loo isticmaalaa in lagu xiro tuubooyinka, waalka, bamka, iyo qalabka kale ee nidaamka tuubooyinka.

2. Qalab la been abuuray - Kuwaas waxaa ka mid ah xusullada, shaatiyada, kuwa wax yareeya, koofiyadaha, iyo ururada loo isticmaalo nidaamyada cadaadiska sare leh.

3. Walxaha - Loogu talagalay xakamaynta socodka dareeraha ee jawiga heerkulka sare leh.

4. Alaabooyin kale oo la been abuuray ama la duubay - Kuwaas waxaa ka mid ah waalka iyo qalabka loo isticmaalo uumiga, gaaska, iyo nidaamyada kale ee cadaadiska sare leh.

Womic Steel, waxaan ku soo saarnaa walxahan cabbirro kala duwan, agab, iyo habayn, annagoo hubinayna inay daboolayaan baahiyahaaga gaarka ah ee codsiga.

Qalabka iyo Halabuurka Kiimikada

Heerka ASTM A182 wuxuu qeexayaa dhowr darajo oo agab ah, oo ay ku jiraan birta kaarboonka, birta dahaarka yar, iyo birta aan daxalka lahayn, mid walbana wuxuu leeyahay shuruudo kiimiko oo gaar ah. Waa kuwan qaar ka mid ah agabka muhiimka ah ee lagu daboolay ASTM A182:

1. Darajada F1 - Bir kaarboon ah oo leh halabuur u oggolaanaya inay ku shaqeyso heerkul dhexdhexaad ah.

2. Darajada F5, F9, F11, F22 – Biraha daawaha hooseeya ee loogu talagalay inay u adkeystaan heerkulka iyo cadaadiska sare.

3. Darajada F304, F304L, F316, F316L – Biraha aan miridhku lahayn ee Austenitic, oo si weyn loogu isticmaalo iska caabbinta daxalka ee deegaanno kala duwan oo kiimikooyin lagu farsameeyo.

Fasal kasta, halabuurka kiimikada si taxaddar leh ayaa loo xakameeyaa si loo daboolo shuruudaha adag ee ASTM. Hoos waxaa ku qoran faahfaahinta halabuurka kiimikada ee walax kasta iyo sifooyinka farsamada.

Qaab-dhismeedka Kiimikada iyo Sifooyinka Farsamada

1. Darajada F1 - Bir Kaarboon ah

Halabuurka Kiimikada:

Kaarboon (C): 0.30-0.60%

Manganese (Mn): 0.60-0.90%

Silikoon (Si): 0.10-0.35%

Sulfur (S): ≤ 0.05%

Fosfooraska (P): ≤ 0.035%

Sifooyinka Farsamada:

Xoogga Jilicsanaanta (MPa): ≥ 485

Xoogga Wax-soo-saarka (MPa): ≥ 205

Kordhinta (%): ≥ 20

2. Darajada F5 - Bir Daawaha Hoose leh

Halabuurka Kiimikada:

Kaarboon (C): 0.10-0.15%

Manganese (Mn): 0.50-0.80%

Chromium (Cr): 4.50-5.50%

Molybdenum (Mo): 0.90-1.10%

Sulfur (S): ≤ 0.03%

Fosfooraska (P): ≤ 0.03%

Sifooyinka Farsamada:

Xoogga Taagista (MPa): ≥ 655

Xoogga Wax-soo-saarka (MPa): ≥ 345

Kordhinta (%): ≥ 20

3. Darajada F304 - Bir aan miridh lahayn oo Austenitic ah

Halabuurka Kiimikada:

Kaarboon (C): ≤ 0.08%

Manganese (Mn): 2.00-2.50%

Chromium (Cr): 18.00-20.00%

Nikkel (Ni): 8.00-10.50%

Sulfur (S): ≤ 0.03%

Fosfooraska (P): ≤ 0.045%

Sifooyinka Farsamada:

Xoogga Jilicsanaanta (MPa): ≥ 515

Xoogga Wax-soo-saarka (MPa): ≥ 205

Kordhinta (%): ≥ 40

4. Darajada F316 - Bir aan miridh lahayn oo Austenitic ah (Dhismaha u adkaysta)

Halabuurka Kiimikada:

Kaarboon (C): ≤ 0.08%

Manganese (Mn): 2.00-3.00%

Chromium (Cr): 16.00-18.00%

Nikkel (Ni): 10.00-14.00%

Molybdenum (Mo): 2.00-3.00%

Sulfur (S): ≤ 0.03%

Fosfooraska (P): ≤ 0.045%

Sifooyinka Farsamada:

Xoogga Jilicsanaanta (MPa): ≥ 515

Xoogga Wax-soo-saarka (MPa): ≥ 205

Kordhinta (%): ≥ 40

Sifooyinka Farsamada iyo Shuruudaha Saamaynta

Sifooyinka farsamada sida xoogga jiidista, xoogga wax soo saarka, iyo dheereynta ayaa muhiim u ah hubinta in qaybaha la been abuuray ay si kalsooni leh u shaqeeyaan iyadoo cadaadis la saarayo. ASTM A182 waxay qeexaysaa sifooyinkan heer kasta oo agab ah, iyadoo shuruudaha ay kala duwan yihiin iyadoo lagu saleynayo xaaladaha codsiga.

Tijaabada saameyntawaa qayb kale oo muhiim ah oo ka mid ah heerka, taasoo hubinaysa in qaybaha la been abuuray ay u adkeysan karaan isbeddellada degdega ah ee heerkulka ama saameynta. Tusaale ahaan, heerkani wuxuu u baahan karaa tijaabo Charpy V-notch ah si loo hubiyo adkaanta xaaladaha heerkulka hooseeya.

Habraacyada Wax Soo Saarka iyo Shuruudaha Daaweynta Kulaylka

Womic Steel waxay raacdaa habab wax soo saar oo adag si loo hubiyo in dhammaan alaabada ASTM A182 ay buuxiyaan heerarka tayada ugu sarreeya. Tan waxaa ka mid ah:

Abuurista iyo Rogidda – Mashiinadayada casriga ah waxay hubinayaan in qayb kasta la sameeyay ama la duubay cabbirro sax ah iyo dulqaad.

Daaweynta Kulaylka – Daaweynta kulaylka ayaa muhiim u ah gaaritaanka sifooyinka farsamada ee la rabo. ASTM A182 waxay u baahan tahay wareegyo daaweyn kuleyl gaar ah iyadoo ku xiran heerka maaddada, sida annealing, deminta, iyo tempering si loo hagaajiyo adkeysiga iyo xoogga.

Alxanka – Waxaan bixinaa xalal alxan oo gaar ah oo loogu talagalay alaabada ASTM A182, annagoo hubinayna isku xirnaan la isku halleyn karo oo aan daadan karin. Habraacyada alxanka si taxaddar leh ayaa loo xakameeyaa si loo hubiyo in qaybaha alxanka ay buuxiyaan ama ka badan yihiin xoogga agabka salka.

Kormeerka iyo Tijaabada

Waxaan sameynaa waxqabad dhammaystirankormeerka iyo tijaabadasi loo xaqiijiyo in dhammaan alaabtu ay buuxiyaan heerka ASTM A182. Tan waxaa ka mid ah:

Baarista Aragga – Cilladaha dusha sare ama cilladaha.

Tijaabada Aan Wax Burbur Ahayn (NDT) - Waxaa ku jira baaritaanka ultrasound-ka iyo baaritaanka raajada si loo ogaado cilladaha gudaha.

Imtixaanka Farsamada - Xoogga jiidista, xoogga wax soo saarka, iyo tijaabada saameynta si loo xaqiijiyo waxqabadka walaxda iyadoo la raacayo cadaadiska.

Falanqaynta Kiimikada – Hubinta in halabuurka kiimikada uu waafaqsan yahay tilmaamaha heerka.

Dhammaan alaabtayadu waxay maraan habraacyo adag oo lagu xakameynayo tayada, waxaanan bixinnaa shahaadooyin faahfaahsan oo ku saabsan u hoggaansanaanta dalab kasta.

Qeexitaannada Badeecada iyo Kala Duwanaanshaha Cabbirka

At Birta Womic, waxaan bixinaa noocyo badan oo badeecooyin ASTM A182 ah oo cabbirro iyo qeexitaanno kala duwan leh.baaxadda cabbirkawaxaa ka mid ah:

Flangesdhexroorka: Laga bilaabo 1/2" ilaa 60" dhexroor.

Qalabka la been abuurayDhexroorka: Laga bilaabo 1/2" ilaa 48" dhexroor.

Qalabyada: Cabbirro gaar ah oo ku habboon shuruudaha nidaamkaaga.

Badeecadahayagu waxay ku diyaar yihiin qiimeyn cadaadis iyo agab kala duwan, taasoo hubinaysa inaan dabooli karno baahiyaha gaarka ah ee mashruucaaga.

Faa'iidooyinka Baakadaha, Maraakiibta, iyo Gaadiidka

Waxaan fahamsanahay muhiimadda keenista waqtiga ku habboon iyo amniga. Womic Steel waxay bixisaaBaakad la habeeyeytaasi oo ilaalinaysa hufnaanta badeecadaha inta lagu jiro safarka. Hadday tahay maraakiib konteenaraysan ama xalal gaar ah oo xamuul ah, waxaan hubinaynaa in dalabkaagu uu ku yimaado waqtigii loogu talagalay oo uu ku jiro xaalad qumman.

Annagakhibradda gaadiidkaiyo iskaashiga tooska ah ee shirkadaha maraakiibta ayaa noo oggolaanaya inaan bixinno qiimo tartan iyo xalal raritaan oo dabacsan.

Habaynta iyo Adeegyada Dheeraadka ah

Marka laga soo tago noocyada kala duwan ee badeecadaha caadiga ah, Womic Steel waxay bixisaawax soo saar gaar ahShuruudaha gaarka ah. Waxaan wax ka beddeli karnaa cabbirrada, agabka, iyo dhammaystirka si ay ugu habboonaadaan codsigaaga gaarka ah.

Adeegyada Habayntawaxaa ka mid ah:

Makiinadaha - Si aad u hesho hagaajin sax ah oo ku habboon baahiyahaaga.

Alxanka - Wixii xiriiro flange ah oo loo habeeyay ama qalabaysan.

Adeegyada Dahaarka iyo Ka-hortagga Daxalka – Bixinta ilaalin waarta oo ku salaysan baahiyahaaga deegaanka.

Maxaad u Dooranaysaa Birta Womic?

Awoodda Wax-soo-saarka: Waxaan leenahay xarumo wax soo saar oo casri ah oo leh awoodo wax soo saar oo heer sare ah.

Khabiir Farsamo: Kooxdeennu waxay ka kooban tahay injineero iyo farsamoyaqaanno xirfad sare leh oo ka go'an soo saarista badeecooyin tayo sare leh.

Faa'iidada Silsiladda SahaydaWaxaan xiriir adag la leenahay alaab-qeybiyeyaasha alaabta ceeriin ah, annagoo hubinayna in si degdeg ah loo keeno oo faa'iidooyin kharash ahna la helo.

Ikhtiyaarada Habaynta: Waxaan bixinaa xalal dabacsan si loo daboolo shuruudaha mashruuca gaarka ah, oo ay ku jiraan alxanka, mashiinka, iyo dahaarka.

Gunaanad

TheHeerka ASTM A182Waxay hubisaa isku halaynta iyo waxqabadka alaabada birta la been abuuray iyo kuwa la duubay ee codsiyada muhiimka ah. Womic Steel waa lammaanahaaga lagu kalsoon yahay ee alaabada tayada sare leh ee loo sameeyay heerkan, iyadoo bixisa taageero dhammaystiran laga bilaabo qeexitaannada farsamada ilaa saadka. Hadday tahay inaad u baahan tahay cabbirro gaar ah, alxan, ama dahaadh gaar ah, waxaanu bixinaa xalal loogu talagalay baahiyahaaga, annagoo hubinayna waxqabad sare iyo isku hallayn gaarsiineed.

Mareegta internetka: www.womicsteel.com

Iimaylka: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 ama Jack: +86-18390957568

Waqtiga boostada: Abriil-21-2025