1. Dulmar Guud oo ku saabsan Badeecada

Womic Steel waa shirkad lagu kalsoon yahay oo soo saarta tuubooyinka naxaasta ee tayo sare leh oo u hoggaansanASTM B88heerarka, gaar ahaan heerarka,Nooca Lqeexitaan laga sameeyayC12200 (fosfooras-ka-dilaacsan, fosfooras haraaga sare leh)naxaas. Tuubooyinkan naxaasta adag ayaa si weyn loogu isticmaalaatuubooyinka, HVAC, ilaalinta dabka, gaaska, iyo nidaamyada guud ee korontadasababtoo ah iska caabbinta daxalka ee aadka u fiican, cimri dhererkooda, iyo qaab-dhismeedkooda.

Naxaasta C12200 waxay ka kooban tahay boqolkiiba sare oo naxaas saafi ah iyo xaddi yar oo fosfooraska ah, taasoo kor u qaadaysa alxanka iyo iska caabbinta burburka haydarojiin. Tuubooyinka Nooca L waxay sameeyaan dheelitirnaan ku habboon oo u dhexeeya dhumucda derbiga iyo miisaanka, iyagoo bixiya isku hallayn labadaba rakibaadda dhulka korkiisa iyo dhulka hoostiisa.

2. Kala duwanaanshaha wax soo saarka

- Dhexroorka Dibadda (OD):6 mm ilaa 219 mm

- Dhumucda Darbiga (WT):0.3 mm ilaa 10 mm

- Dhererka:Dhererka caadiga ah ee3m, 5m, iyo 6m, oo lehdhererka la habeeyey ayaa la heli karaa marka la codsado

- Tuubooyinka La Duubay:Waxaa laga heli karaaMishiinada 25m ama 50msi loogu rakibo dabacsan oo ku jira beddelayaasha kulaylka

- Dhammaadka Dhammaadka:Dhamaadka caadiga ah, la nadiifiyay oo laga saaray; waxaa laga heli karaa koofiyado ama aan lahayn

3. Dulqaadka Cabbirka (Tuubooyinka Naxaasta ASTM B88 C12200)

Birta Womic waxay hubisaa saxnaanta cabbirka saxda ah eeC12200tuubooyinka waafaqsanASTM B88Heerarka. Dulqaadka soo socda ayaa khuseeya:

ASTM B88 - Shaxda 1: Cabbirrada, Miisaanka, iyo Dulqaadka Cabbirrada Tuubooyinka Biyaha ee Naxaasta ah

| Cabbirka Magacaaban (in.) | Dhexroorka Dibadda (in.) | Dulqaadka OD (La baabi'iyay) | Dulqaadka OD (La sawiray) | Nooca K Darbiga (in.) | Nooca K Tol. (in.) | Nooca Darbiga L (in.) | Nooca L Tol. (in.) | Nooca M Derbiga (in.) | Nooca M Tol. (in.) |

| 1/4 | 0.375 | 0.002 | 0.001 | 0.035 | 0.0035 | 0.03 | 0.003 | C | C |

| 3/8 | 0.5 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.035 | 0.004 | 0.025 | 0.002 |

| 1/2 | 0.625 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.04 | 0.004 | 0.028 | 0.003 |

| 5/8 | 0.75 | 0.0025 | 0.001 | 0.049 | 0.005 | 0.042 | 0.004 | C | C |

| 3/4 | 0.875 | 0.003 | 0.001 | 0.065 | 0.006 | 0.045 | 0.004 | 0.032 | 0.003 |

| 1 | 1.125 | 0.0035 | 0.0015 | 0.065 | 0.006 | 0.05 | 0.005 | 0.035 | 0.004 |

| 1 1/4 | 1.375 | 0.004 | 0.0015 | 0.065 | 0.006 | 0.055 | 0.006 | 0.042 | 0.004 |

| 1 1/2 | 1.625 | 0.0045 | 0.002 | 0.072 | 0.007 | 0.06 | 0.006 | 0.049 | 0.005 |

| 2 | 2.125 | 0.005 | 0.002 | 0.083 | 0.008 | 0.07 | 0.007 | 0.058 | 0.006 |

| 2 1/2 | 2.625 | 0.005 | 0.002 | 0.095 | 0.01 | 0.08 | 0.008 | 0.065 | 0.006 |

| 3 | 3.125 | 0.005 | 0.002 | 0.109 | 0.011 | 0.09 | 0.009 | 0.072 | 0.007 |

| 3 1/2 | 3.625 | 0.005 | 0.002 | 0.12 | 0.012 | 0.1 | 0.01 | 0.083 | 0.008 |

| 4 | 4.125 | 0.005 | 0.002 | 0.134 | 0.013 | 0.11 | 0.011 | 0.095 | 0.01 |

| 5 | 5.125 | 0.005 | 0.002 | 0.160 | 0.016 | 0.125 | 0.012 | 0.109 | 0.011 |

| 6 | 6.125 | 0.005 | 0.002 | 0.192 | 0.019 | 0.14 | 0.014 | 0.122 | 0.012 |

| 8 | 8.125 | 0.008 | 0.002/-0.004 | 0.271 | 0.027 | 0.2 | 0.02 | 0.17 | 0.017 |

| 10 | 10.125 | 0.008 | 0.002/-0.006 | 0.338 | 0.034 | 0.25 | 0.025 | 0.212 | 0.021 |

| 12 | 12.125 | 0.008 | 0.002/-0.006 | 0.405 | 0.04 | 0.28 | 0.028 | 0.254 | 0.025 |

A. Dhexdhexaadiyaha dibadda ee tuubada waa celceliska dhexroorka ugu badan iyo kan ugu yar ee dibadda, sida lagu go'aamiyay qayb kasta oo ka mid ah tuubada.

B Kala leexashada ugu badan ee hal dhibic.

C Waxay tilmaamaysaa in agabka aan guud ahaan la heli karin ama in aan la helin dulqaad

Dulqaadyadani waxay hubinayaan in tuubooyinku ay kulmaanshuruudaha saxda ah iyo tayada sare, taasoo ka dhigaysa kuwo ku habboondalabaad codsiyo warshadeed iyo kuwo badeed ah oo dalbanaya.

3. Halabuurka Kiimikada (C12200 - ASTM B88)

Walax Halabuurka (% miisaan ahaan)

Naxaas (Cu) MinB≥ 99.9 (oo ay ku jirto lacag)

Fosfooraska (P) 0.015 – 0.040

Ogsijiinku waa inuu ahaadaa ugu badnaan 10 ppm.

B Naxaas + qalin ≤ 0.04

Waxyaabaha ku jira fosfooraska waxay hagaajiyaan alxanka iyo iska caabbinta dildilaaca cadaadiska, iyadoo la ilaalinayo kulaylka iyo korantada oo sarreeya.

4. Sifooyinka Farsamada

Tuubada naxaasta adag ee nooca L waxaa badanaa lagu bixiyaa qaab adag (la jiiday), oo ku habboon nidaamyada cadaadiska iyo rakibidda tooska ah.

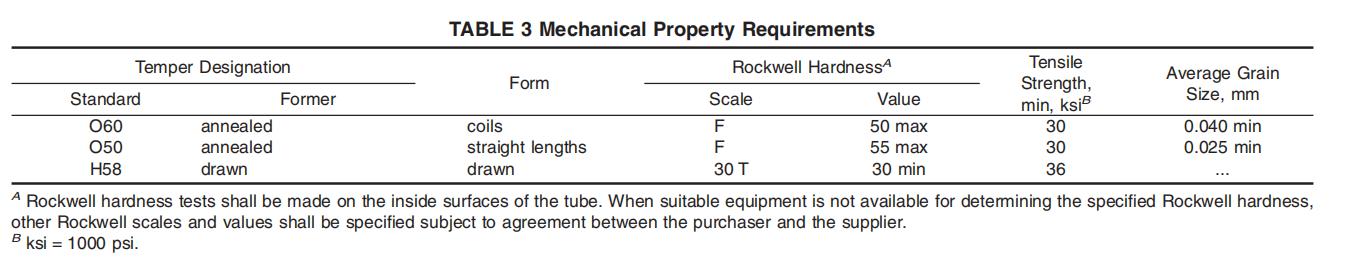

5. Shuruudaha Bixinta

Womic Steel waxay bixisaa tuubooyinka naxaasta ee Nooca L xaaladaha soo socda:

Dabeecad Adag (H58):Dhererka toosan ee nidaamyada cadaadiska

Heerkul la isku daray (O60):Waxaa laga heli karaa codsiyo u baahan foorarsiga iyo sameynta

6. Habka Wax Soo Saarka

Womic Steel waxay hubineysaa saxnaan iyo tayo sare leh iyada oo loo marayo tallaabooyinka soo socda:

- Dhalaalidda & Tuuridda:Naxaasta saafiga ah ee sare ayaa dhalaalaysa oo lagu shubayaa billets.

- Kordhinta:Billet-yada waxaa lagu soo saaraa qaab tuubo ah.

- Sawir Qabow:Tuubooyinka waxaa lagu sawiraa cabbirka ugu dambeeya iyo dhumucda.

- Qaboojinta (ikhtiyaar ah):Haddii loo baahdo, kuleyl ayaa lagu daaweeyaa si loo yareeyo xanuunka.

- Toosinta iyo Jarida:Tuubooyinka waxaa loo gooyaa dherer caadi ah ama mid gaar ah.

- Nadiifinta iyo Kormeerka:Dusha sare ee gudaha iyo dibaddaba waa la nadiifiyaa oo la hubiyaa.

- Calaamadaynta iyo Baakaynta:Tuubooyinka waxaa lagu calaamadeeyay ASTM B88, nooca iyo cabbirka si loo raad raaco.

7. Tijaabinta iyo Kormeerka

Womic Steel waxay xaqiijisaa heerarka tayada ugu sarreeya iyadoo fulinaysabaaritaan iyo kormeer adag, oo ay ku jiraan:

- Falanqaynta Halabuurka Kiimikada:Xaqiijinta iyadoo la adeegsanayo falanqaynta kiimikada ee sawir-qaadista ama qoyan

- Tijaabada Tijaabada:Hubinta xoogga iyo dhererka waa inay buuxiyaan shuruudaha ASTM B88

- Tijaabada Adkaanta:Lagu cabbiray iyadoo la isticmaalayoHabka Vickers

- Imtixaanka Ballaarinta Waddada:Ballaarinta tuubada ayaa ku dhammaatay30%iyadoo la isticmaalayo a45° mandrel koonikada ah

- Tijaabada Fiditaanka:Qiimayntaisbeddel iyo iska caabinta dildilaaca

- Imtixaanka Hadda ee Eddy (ECT):Ogaanshahacilladaha dusha sare iyo dhulka hoostiisa

- Tijaabada Cadaadiska Hydrostatic-ka:Hubinta in tuubooyinku ay u adkaystaancadaadiska gudaha iyada oo aan daadanayn

8. Muunad qaadis

Saami-qaadista iyo tijaabada waxaa lagu sameeyaa iyadoo la raacayo ASTM B88 iyo hab-raacyada QA ee gudaha. Saami-qaadyada tijaabada waxaa si aan kala sooc lahayn looga soo xulaa qayb kasta si loogu sameeyo:

Waxyaabaha kiimikada ku jira

l sifooyinka farsamada

saxnaanta cabbirka l

Xaaladda dusha sare

9. Baakad

Si loo hubiyomaarayn iyo gaadiid ammaan ah, Womic Steel waxay bixisaaxalalka baakadaha adag, oo ay ku jiraan:

- Dahaarka Ka-hortagga Oksaydhaynta:Lakabka ilaalinta ayaa la mariyey si looga hortago daxalka inta lagu jiro kaydinta iyo rarista

- Koofiyadaha Dhammaadka:Dabool balaastig ah ama bir ah oo ku yaal dhammaadka tuubada si looga hortago wasakhowga

- Isku-xidhka:Xariijimo ammaan ah oo leh xargaha balaastikada ama birta si loo xasiliyo

- God alwaax ah:Ku xiransanduuqyo alwaax ah oo u adkaysta qoyaankaoo leh dahaar xumbo ilaalin ah

- Calaamadaynta:Xidhmo kasta waxaa lagu calaamadeeyayOD, WT, dhererka, dabeecadda, lambarka dufcadda, iyo taariikhda wax soo saarka

10. Gaadiidka & Saadka

Birta Womic waxay hubineysaagaarsiinta waqtiga ku habboon oo ammaan ahiyada oo loo marayo:

- Xamuulka Badda:Ammaan ahMaraakiib konteenaraysan oo loogu talagalay qaybinta caalamiga ah

- Gaadiidka Tareenka iyo Waddooyinka:Gaarsiin lagu kalsoonaan karo oo loogu talagalay macaamiisha gobolka

- Maareynta Gaarka ah:Ikhtiyaarada cimilada la xakameeyey ee codsiyada xasaasiga ah

- Dukumentiyo Dhammaystiran:Oo ay ku jiraanShahaadooyinka Imtixaanka Mill (MTC), Warbixinnada U Hoggaansanaanta Agabka, iyo Caymiska

- Iska caabinta Daxalka Sare:Aad ugu fiicancodsiyada wareejinta badda, kiimikada, iyo kulaylka

- Wax soo saarka Sax ah:Adagdulqaadka cabbirkasi loo helo waxqabad wanaagsan

- Xalalka Gaarka ah:Cabbirrada, heerkulka, iyo dahaarka loo habeeyey si loo daboolo shuruudaha gaarka ah

- Tijaabo Dhammaystiran:Hubinta u hoggaansanaanta buuxda eeASTM B88

- Shabakadda Qaybinta Caalamiga ah:Bixinta degdegga ah oo lagu kalsoonaan karo adduunka oo dhan

11. Faa'iidooyinka Doorashada Birta Womic

12. Codsiyada

AnnagaASTM B88 C12200tuubooyinka ayaa ku habboon:

- Warshadaha Badda: Qaboojiyaha biyaha badda lagu qaboojiyo, tuubooyinka, iyo beddelayaasha kulaylka markabka

- Warshadaha Korontada:Kondenser-ka uumiga iyonidaamyada qaboojinta

- Warshad Sifeyn ah:Tuubooyinka u adkaysta daxalka ee loogu talagalay isticmaalka biyaha cusbada leh

- Habaynta Kiimikada:Tuubooyinka isku beddelka kulaylka cadaadiska sare leh, heerkulka sare leh

- HVAC & Qaboojiyaha: Gariiradaha qaboojiyaha iyo nidaamyada qaboojinta warshadaha

Gunaanad

Tuubooyinka naxaasta ee ASTM B88 C12200 Nooca L ee Womic Steel waxay bixiyaan waxqabad heer sare ah, cimri dherer, iyo iska caabin daxalka, taasoo ka dhigaysa xulasho la door bidayo oo loogu talagalay noocyo badan oo nidaamyada tuubooyinka ah. Iyadoo si adag loo raacayo heerarka ASTM iyo hubinta tayada oo dhammaystiran, waxaan hubineynaa in gaarsiin kasta ay buuxiso filashooyinka ugu sarreeya ee shaqeynta iyo isku halaynta.

Waxaan ku faannaa annagaadeegyada habaynta, wareegyada wax soo saarka degdega ah, iyoshabakadda gaarsiinta caalamiga ah, hubinta in baahiyahaaga gaarka ah lagu daboolay saxnaan iyo heer sare.

Mareegta internetka: www.womicsteel.com

Iimaylka: sales@womicsteel.com

Tel/WhatsApp/WeChat: Victor: +86-15575100681 ama Jack: +86-18390957568

Waqtiga boostada: Jan-21-2026