Sharaxaadda Badeecada

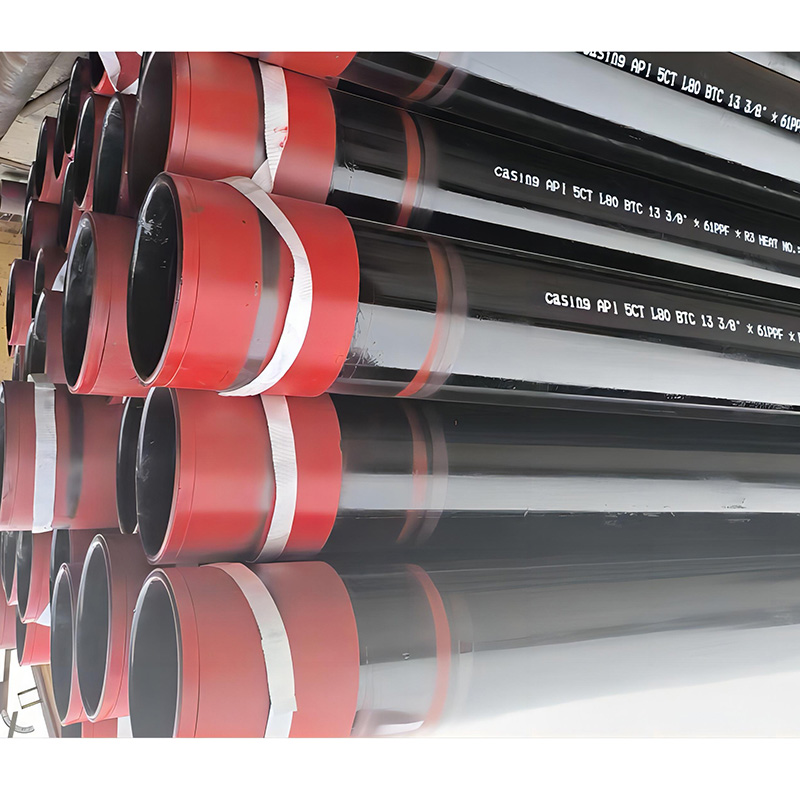

Daboolka iyo tuubooyinka oo si weyn loogu isticmaalo horumarinta saliidda iyo gaaska, Daboolka iyo tuubooyinku waa qaybo muhiim u ah warshadaha saliidda iyo gaaska ee loo isticmaalo soo saarista iyo rarista hydrocarbons (saliidda iyo gaaska dabiiciga ah) laga soo bilaabo kaydka dhulka hoostiisa ilaa dusha sare. Waxay door muhiim ah ka ciyaaraan hubinta badbaadada, hufnaanta, iyo hufnaanta hawlaha qodista iyo wax soo saarka.

Tuubbooyinku waa nooc ka mid ah dhuumaha loo isticmaalo in saliidda cayriin iyo gaaska dabiiciga ah laga soo wareejiyo lakabka saliidda ama lakabka gaaska dhulka ka dib marka la dhammeeyo qodista. Qasacadda tuubooyinku waxay u oggolaanaysaa cadaadiska ka dhasha habka soo saarista. Tuubbooyinku waxay soo saaraan si la mid ah sida dahaarka, laakiin habka loo yaqaan "xanaaq" ayaa sidoo kale loo baahan yahay si loo qariyo tuubada tuubbooyinka.

Daboolka waxaa loo isticmaalaa in lagu ilaaliyo godadka ceelasha ee dhulka loo qoday si saliid loogu helo. Sida tuubada qodista, tuubooyinka ceelasha saliidda ayaa sidoo kale u oggolaanaya cadaadiska xiisadda axial, sidaa darteed waxaa loo baahan yahay bir tayo sare leh oo xoog badan. Daboolka OCTG waa tuubooyin dhexroor weyn leh oo lagu simi karo godka.

Tilmaamaha

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| API 5CT: J55, K55, N80, L80, P110 |

| API 5D: E75, X95, G105, S135 |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A106: GR.A, GR.B, GR.C |

| ASTM A53/A53M: GR.A, GR.B |

| ASTM A335: P1, P2, 95, P9, P11P22, P23, P91, P92, P122 |

| ASTM A333: Gr.1, Gr.3, Gr.4, Gr.6, Gr.7, Gr.8, Gr.9.Gr.10, Gr.11 |

| DIN 2391: St30Al, St30Si, St35, St45, St52 |

| DIN EN 10216-1: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| JIS G3454: STPG 370, STPG 410 |

| JIS G3456: STPT 370, STPT 410, STPT 480 |

| GB/T 8163: 10#, 20#, Q345 |

| GB/T 8162: 10#, 20#, 35#, 45#, Q345 |

Liiska Daboolka Birta ISO/API

| Calaamadahaa | Dibadda dhexroor D mm | Magac-u-yaal toosan cufnaanb, c Shuruudaha iyo Xeerarka kg/m | Derbiga dhumucdiisuna waa t mm | Nooca dhammaadka-dhammaadka | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nooca 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 9.50 10.50 11.60 13.50 15.10 | 114,30 114,30 114,30 114,30 114,30 | 14,14 15,63 17,26 20,09 22,47 | 5,21 5,69 6,35 7,37 8,56 | PS — — — — | PS PSB PSLB — — | PS PSB PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB — | — — PLB PLB PLB | — — — — PLB |

| 5 5 5 5 5 5 5 | 11.50 13.00 15.00 18.00 21.40 23.20 24.10 | 127,00 127,00 127,00 127,00 127,00 127,00 127,00 | 17,11 19,35 22,32 26,79 31,85 34,53 35,86 | 5,59 6,43 7,52 9,19 11,10 12,14 12,70 | — — — — — — — | PS PSLB PSLBE — — — — | PS PSLB PLB PLB PLB — — | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — PLBE PLBE PLB PLB PLB | — — — PLBE PLB PLB PLB |

| 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 5-1/2 | 14.00 15.50 17.00 20.00 23.00 26.80 29.70 32.60 35.30 38.00 40.50 43.10 | 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 139,70 | 20,83 23,07 25,30 29,76 34,23 39,88 44,20 48,51 52,53 56,55 60,27 64,14 | 6,20 6,98 7,72 9,17 10,54 12,70 14,27 15,88 17,45 19,05 20,62 22,22 | PS | PS PSLBE PSLBE | PS PSLB PLB PLB PLB | — — PLBE PLBE PLBE — — — — — — — | PLBE PLBE PLBE | PLBE PLBE PLBE P P P P P P P | PLBE PLBE PLBE | — — — — PLBE — — — — — — |

| 6-5/8 6-5/8 6-5/8 6-5/8 | 20.00 24.00 28.00 32.00 | 168,28 168,28 168,28 168,28 | 29,76 35,72 41,67 47,62 | 7,32 8,94 10,59 12,06 | PS — — | PSLB PSLBE — | PSLB PLB PLB — | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — PLBE PLBE PLBE | — — PLBE |

| 7 7 7 7 7 7 7 7 7 7 7 7 7 | 17.00 20.00 23.00 26.00 29.00 32.00 35.00 38.00 42.70 46.40 50.10 53.60 57.10 | 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 177,80 | 25,30 29,76 34,23 38,69 43,16 47,62 52,09 56,55 63,54 69,05 74,56 79,77 84,97 | 5,87 6,91 8,05 9,19 10,36 11,51 12,65 13,72 15,88 17,45 19,05 20,62 22,22 | PS PS — — — — — — — — — — — | — PS PSLBE PSLBE — — — — — — — — — | — PS PLB PLB PLB PLB — — — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE — — — — — | — — PLBE PLBE PLBE PLBE PLBE PLBE P P P P P | — — — PLBE PLBE PLBE PLBE PLBE — — — — — | — — — — — — PLBE PLBE — — — — — |

| Fiiri qoraallada ku yaal dhammaadka jadwalka. | ||||||||||||

| Calaamadahaa | Dibadda dhexroor D mm | Magac-u-yaal toosan cufnaanb, c Shuruudaha iyo Xeerarka kg/m | Derbiga dhumucdiisuna waa t mm | Nooca dhammaadka-dhammaadka | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nooca 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 7-5/8 | 24.00 26.40 29.70 33.70 39.00 42.80 45.30 47.10 51.20 55.30 | 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 193,68 | 35,72 39,29 44,20 50,15 58,04 63,69 67,41 70,09 76,19 82,30 | 7,62 8,33 9,52 10,92 12,70 14,27 15,11 15,88 17,45 19,05 | PS | PSLBE | PSLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB | PLBE PLBE PLBE PLBE PLB PLB PLB P P | PLBE PLBE PLBE PLB PLB PLB | PLBE PLB PLB PLB |

| 7-3/4 | 46.10 | 19,685 | 6,860 | 1,511 | — | — | — | P | P | P | P | P |

| 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 8-5/8 | 24.00 28.00 32.00 36.00 40.00 44.00 49.00 | 219,08 219,08 219,08 219,08 219,08 219,08 219,08 | 35,72 41,67 47,62 53,57 59,53 65,48 72,92 | 6,71 7,72 8,94 10,16 11,43 12,70 14,15 | PS PS — — — — | PS — PSLBE PSLBE — — — | PS PS PSLB PSLB PLB — — | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — PLBE PLBE PLBE PLBE | — — — — PLBE PLBE PLBE | — — — — — — PLBE |

| 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 9-5/8 | 32.30 36.00 40.00 43.50 47.00 53.50 58.40 59.40 64.90 70.30 75.60 | 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 244,48 | 48,07 53,57 59,53 64,73 69,94 79,62 86,91 88,40 96,58 104,62 112,50 | 7,92 8,94 10,03 11,05 11,99 13,84 15,11 15,47 17,07 18,64 20,24 | PS PS — — — — — — — — — | — PSLB PSLBE — — — — — — — — | — PSLB PSLB PLB PLB — — — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB — — — — | — — PLBE PLBE PLBE PLBE PLB P P P P | — — — PLBE PLBE PLBE PLB — — — — | — — — — PLBE PLBE PLB — — — — |

| 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 10-3/4 | 32.75 40.50 45.50 51.00 55.50 60.70 65.70 73.20 79.20 85.30 | 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 273,05 | 48,74 60,27 67,71 75,90 82,59 90,33 97,77 108,93 117,86 126,94 | 7,09 8,89 10,16 11,43 12,57 13,84 15,11 17,07 18,64 20,24 | PS PS | PSB PSBE PSBE | PSB PSB PSB PSB | PSBE PSBE | PSBE PSBE | PSBE PSBE PSBE PSB P P P | PSBE PSBE PSBE PSB | PSBE PSB |

| 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 11-3/4 | 42.00 47.00 54.00 60.00 65.00 71.00 | 298,45 298,45 298,45 298,45 298,45 298,45 | 62,50 69,94 80,36 89,29 96,73 105,66 | 8,46 9,53 11,05 12,42 13,56 14,78 | PS — — — | PSB PSB PSB — — | PSB PSB PSB — — | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P | — — PSB P P |

| 13-3/8 13-3/8 13-3/8 13-3/8 13-3/8 | 48.00 54.50 61.00 68.00 72.00 | 339,72 339,72 339,72 339,72 339,72 | 71,43 81,10 90,78 101,19 107,15 | 8,38 9,65 10,92 12,19 13,06 | PS — — — — | — PSB PSB PSB — | — PSB PSB PSB — | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — PSB PSB | — — — — PSB |

| Fiiri qoraallada ku yaal dhammaadka jadwalka. | ||||||||||||

| Calaamadahaa | Dibadda dhexroor D mm | Magac-u-yaal toosan cufnaanb, c Shuruudaha iyo Xeerarka kg/m | Derbiga dhumucdiisuna waa t mm | Nooca dhammaadka-dhammaadka | ||||||||

| 1 | 2 | H40 | J55 K55 | M65 | L80 C95 | N80 Nooca 1, Q | C90 T95 | P110 | Q125 | |||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 |

| 16 16 16 16 | 65.00 75.00 84.00 109.00 | 406,40 406,40 406,40 406,40 | 96,73 111,61 125,01 162,21 | 9,53 11,13 12,57 16,66 | PS | PSB PSB P | PSB PSB | P | P | P | P | |

| 18-5/8 | 87.50 | 47,308 | 13,021 | 1,105 | PS | PSB | PSB | — | — | — | — | — |

| 20 20 20 | 94.00 106.50 133.00 | 508,00 508,00 508,00 | 139,89 158,49 197,93 | 11,13 12,70 16,13 | PSL — — | PSLB PSLB PSLB | PSLB PSLB — | — — — | — — — | — — — | — — — | — — — |

| P = Dhammaad caadi ah, S = Dun wareegsan oo gaaban, L = Dun wareegsan oo dheer, B = Dun dabada, E = Xariiq aad u daran. | ||||||||||||

| ♦ Calaamadaha waxaa loogu talagalay macluumaad iyo caawimo ku saabsan dalbashada. ♦ Cufnaan toosan oo magac leh, oo dunta lagu dhejiyay oo la isku xidhay (col. 2) ayaa loo muujiyay macluumaad keliya. ♦ Cufnaanta birta chromium-ka ee martensitic (noocyada L80 9Cr iyo 13Cr) way ka duwan yihiin birta kaarboon. Sidaa darteed cufnaanta la muujiyay sax uma aha birta chromium-ka ee martensitic. Waxaa la isticmaali karaa qodob sax ah oo ah 0,989. | ||||||||||||

| Calaamadaha | Dhexroorka dibadda D mm | Toosan oo toosan cufnaan kg/m | Dhumucda derbiga t mm | |

| 1 | 2 | |||

| 1 | 2 | 3 | 4 | 5 |

| 3-1/2 4 4-1/2 5 5-1/2 6-5/8 | 9.92 11.35 13.05 17.95 19.83 27.66 | 88,90 101,60 114,30 127,00 139,70 168,28 | 14,76 16,89 19,42 26,71 29,51 41,18 | 7,34 7,26 7,37 9,19 9,17 10,59 |

Liiska Tuubooyinka Birta ISO/API

| Calaamadaha | Dibadda dhexroor D mm | Toosan oo magac leh tiro badana, b | Derbiga dhumuc weyn- waalli t mm | Nooca dhammaadka dhammaadkac | |||||||||||

| Aan- xanaaqsan Shuruudaha iyo Xeerarka kg/m | Dheeraad. xanaaqsan Shuruudaha iyo Xeerarka kg/m | Isku-dhafan. kala-goys kg/m | |||||||||||||

| 1 | 2 | ||||||||||||||

| NU Shuruudaha iyo Xeerarka | EU Shuruudaha iyo Xeerarka | IJ | H40 | J55 | L80 | N80 Nooca 1, Q | C90 | T95 | P110 | ||||||

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 |

| 1,900 1,900 1,900 1,900 1,900 | 2.40 2.75 3.65 4.42 5.15 | — 2.90 3.73 — — | 2.40 2.76 — — — | 48,26 48,26 48,26 48,26 48,26 | — 4,09 5,43 6,58 7,66 | — 4,32 5,55 — — | 3,57 4,11 — — — | 3,18 3,68 5,08 6,35 7,62 | PI PNUI PU — — | PI PNUI PU — — | — PNUI PU P P | — PNUI PU — — | — PNUI PU P P | — PNUI PU P P | PU — — |

| 2.063 2.063 | 3.24 4.50 | — — | 3.25 — | 52,40 52,40 | — — | — — | 4,84 — | 3,96 5,72 | PI P | PI P | PI P | PI P | PI P | PI P | P |

| 2-3/8 2-3/8 2-3/8 2-3/8 2-3/8 | 4.00 4.60 5.80 6.60 7.35 | 4.70 5.95 7.45 | 60,32 60,32 60,32 60,32 60,32 | 5,95 6,85 8,63 9,82 10,94 | 6,99 8,85 11,09 | 4,24 4,83 6,45 7,49 8,53 | PN PNU-ga | PN PNU-ga | PN PNU-ga PNU-ga P PU | PN PNU-ga PNU-ga — — | PN PNU-ga PNU-ga P PU | PN PNU-ga PNU-ga P PU | PNU-ga PNU-ga | ||

| 2-7/8 2-7/8 2-7/8 2-7/8 | 6.40 7.80 8.60 9.35 | 6.50 7.90 8.70 9.45 | — — — | 73,02 73,02 73,02 73,02 | 9,52 11,61 12,80 13,91 | 9,67 11,76 12,95 14,06 | — — — | 5,51 7,01 7,82 8,64 | PNU-ga — — | PNU-ga — — | PNU-ga PNU-ga PNU-ga PU | PNU-ga PNU-ga PNU-ga — | PNU-ga PNU-ga PNU-ga PU | PNU-ga PNU-ga PNU-ga PU | PNU-ga PNU-ga PNU-ga — |

| 2-7/8 2-7/8 | 10.50 11.50 | — | — | 73,02 73,02 | 15,63 17,11 | — | — | 9,96 11,18 | — | — | P P | — | P P | P P | — |

| 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 3-1/2 | 7.70 9.20 10.20 12.70 14.30 15.50 17.00 | — 9.30 — 12.95 — — — | — — — — — — — | 88,90 88,90 88,90 88,90 88,90 88,90 88,90 | 11,46 13,69 15,18 18,90 21,28 23,07 25,30 | — 13,84 — 19,27 — — — | — — — — — — — | 5,49 6,45 7,34 9,52 10,92 12,09 13,46 | PN PNU-ga PN — — — — | PN PNU-ga PN — — — — | PN PNU-ga PN PNU-ga P P P | PN PNU-ga PN PNU-ga — — — | PN PNU-ga PN PNU-ga P P P | PN PNU-ga PN PNU-ga P P P | — PNU-ga — PNU-ga — — — |

| 4 4 4 4 4 4 | 9.50 10.70 13.20 16.10 18.90 22.20 | — 11.00 — — — — | — — — — — — | 101,60 101,60 101,60 101,60 101,60 101,60 | 14,14 — 19,64 23,96 28,13 33,04 | — 16,37 — — — — | — — — — — — | 5,74 6,65 8,38 10,54 12,70 15,49 | PN PU — — — — | PN PU — — — — | PN PU P P P P | PN PU — — — — | PN PU P P P P | PN PU P P P P | — — — — — — |

| 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 4-1/2 | 12.60 15.20 17.00 18.90 21.50 23.70 26.10 | 12.75 | 114,30 114,30 114,30 114,30 114,30 114,30 114,30 | 18,75 22,62 25,30 28,13 32,00 35,27 38,84 | 18,97 | 6,88 8,56 9,65 10,92 12,70 14,22 16,00 | PNU-ga | PNU-ga | PNU-ga P P P P P P | PNU-ga — — — — — — | PNU-ga P P P P P P | PNU-ga P P P P P P | |||

| P = Dhammaad caadi ah, N = Ma aha mid aan xanaaqsanayn oo isku xiran, U = Maqas dibadda ah oo kacsan oo isku xiran, I = Kala-goysyada Isku-dhafan. | |||||||||||||||

| ♦ Cufnaanta toosan ee magacaaban, dunta iyo isku xidhka (col. 2, 3, 4) waxaa loo muujiyay macluumaad keliya. ♦ Cufnaanta birta chromium-ka ee martensitic (noocyada L80 9Cr iyo 13Cr) way ka duwan yihiin birta kaarboon. Sidaa darteed cufnaanta la muujiyay sax uma aha birta chromium-ka ee martensitic. Waxaa la isticmaali karaa qodob sax ah oo ah 0,989. ♦ Tuubbo aan dhibsanayn ayaa la heli karaa iyadoo la isticmaalayo isku-xidhka caadiga ah ama isku-xidhka bevel-ka gaarka ah. Tuubbo dibadda ah oo dhibsanaysa ayaa la heli karaa iyadoo la adeegsanayo isku-xidhka caadiga ah, kan gaarka ah, ama kan gaarka ah ee nadiifinta. | |||||||||||||||

Heerka & Darajada

Daboolka iyo tuubada Heerarka caadiga ah:

API 5CT J55,K55,L80, N80,P110, C90, T95, H40

Daboolka API 5CT iyo dhammaadka tuubooyinka tuubada:

(STC)Qalabka dunta wareegsan oo gaaban

(LC) Qasabadda dunta wareegsan oo dheer

(BC)Qalabka dunta ee Buttertress

Qasabadda xariiqda aadka u daran (XC)

(NU) Tuubo aan xanaaqsanayn

Tuubo dibadda ah oo kacsan (EU)

(IJ) Tuubo isku-dhafan

Qashinka iyo tuubooyinka waa inay ahaadaan kuwo la keenayo iyadoo loo eegayo xiriirka kor ku xusan ee heerka API5CT / Heerarka API.

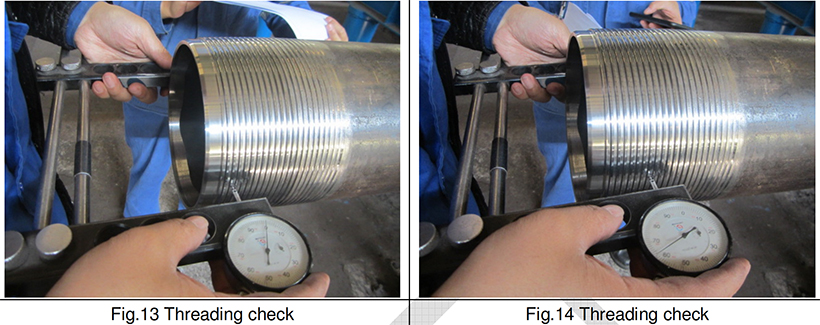

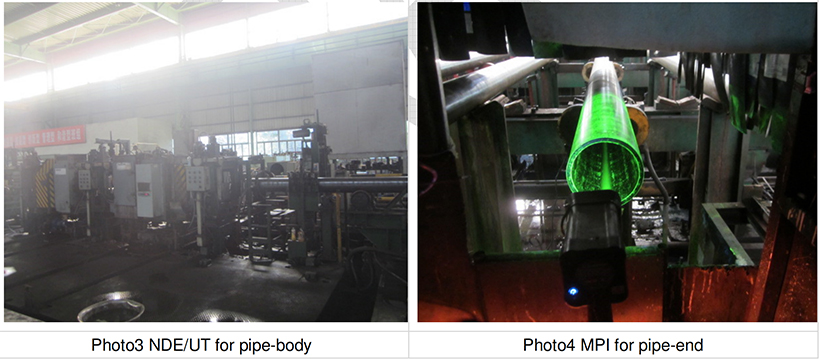

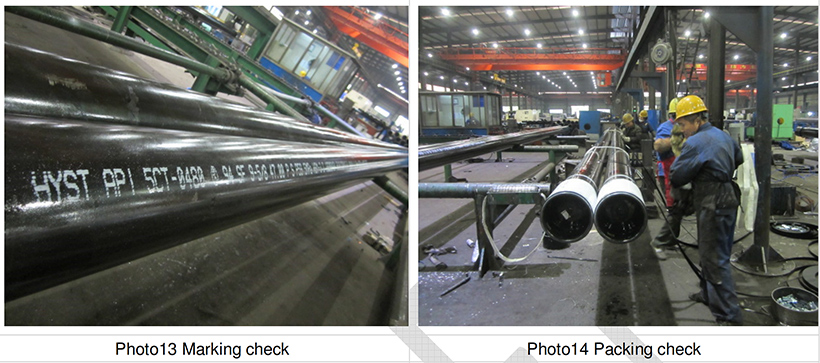

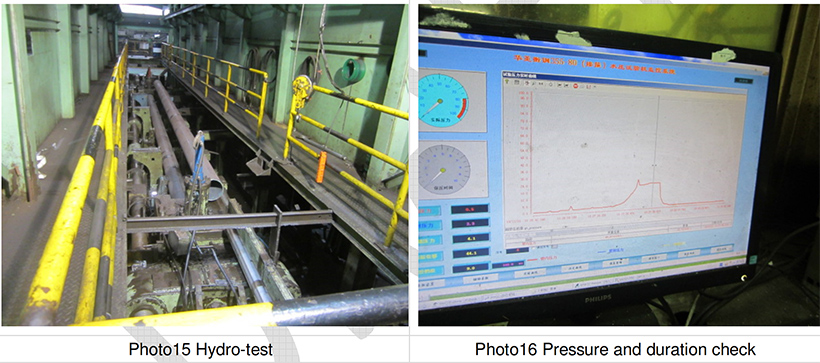

Xakamaynta Tayada

Hubinta Walxaha Cayriin, Falanqaynta Kiimikada, Tijaabada Farsamada, Kormeerka Aragga, Tijaabada Xiisadda, Hubinta Cabbirka, Tijaabada Laabista, Tijaabada Fiditaanka, Tijaabada Saamaynta, Tijaabada DWT, Tijaabada NDT, Tijaabada Hydrostatic, Tijaabada Adkaanta…..

Calaamadaynta, Rinjiyeynta ka hor inta aan la keenin.

Xirmooyinka iyo Rarista

Habka baakadaha ee tuubooyinka birta ah waxaa ka mid ah nadiifinta, kooxaynta, duubista, xidhista, sugidda, calaamadaynta, baaldiyeynta (haddii loo baahdo), kaydinta weelasha, kaydinta, shaabadaynta, rarista, iyo furfurista. Noocyo kala duwan oo tuubooyinka birta ah iyo qalabka ku rakiban oo leh habab kala duwan oo baakadayn ah. Habkan dhammaystiran wuxuu hubinayaa in tuubooyinka birta ah la raro oo la gaaro meeshii loogu talagalay xaalad wanaagsan, oo diyaar u ah isticmaalkooda loogu talagalay.

Isticmaalka & Codsiga

Tuubooyinka birta ah waxay u adeegaan laf-dhabarta injineernimada warshadaha casriga ah iyo tan madaniga ah, iyagoo taageeraya codsiyo badan oo gacan ka geysta horumarinta bulshooyinka iyo dhaqaalaha adduunka oo dhan.

Tuubooyinka birta ah iyo qalabka aan soo saarnay ee Womic Steel si weyn ayaa loogu isticmaalaa dhuumaha batroolka, gaaska, shidaalka iyo biyaha, xeebaha/dhulka, mashaariicda dhismaha dekadda badda iyo dhismaha, qodista, Birta qaab-dhismeedka, mashaariicda dhismaha buundooyinka, iyo sidoo kale tuubooyinka birta saxda ah ee wax soo saarka duubista, iwm...