Sharaxaadda Badeecada

Tuubooyinka birta wareegsan, oo sidoo kale loo yaqaan tuubooyinka helical submerged arc-welded (HSAW), waa nooc ka mid ah tuubooyinka birta ah oo lagu garto habka wax soo saarka ee gaarka ah iyo sifooyinka qaab-dhismeedka. Tuubooyinkan waxaa si weyn loogu isticmaalaa warshado kala duwan sababtoo ah xooggooda, cimrigooda, iyo la qabsigooda. Waa kan sharraxaad faahfaahsan oo ku saabsan tuubooyinka birta wareegsan:

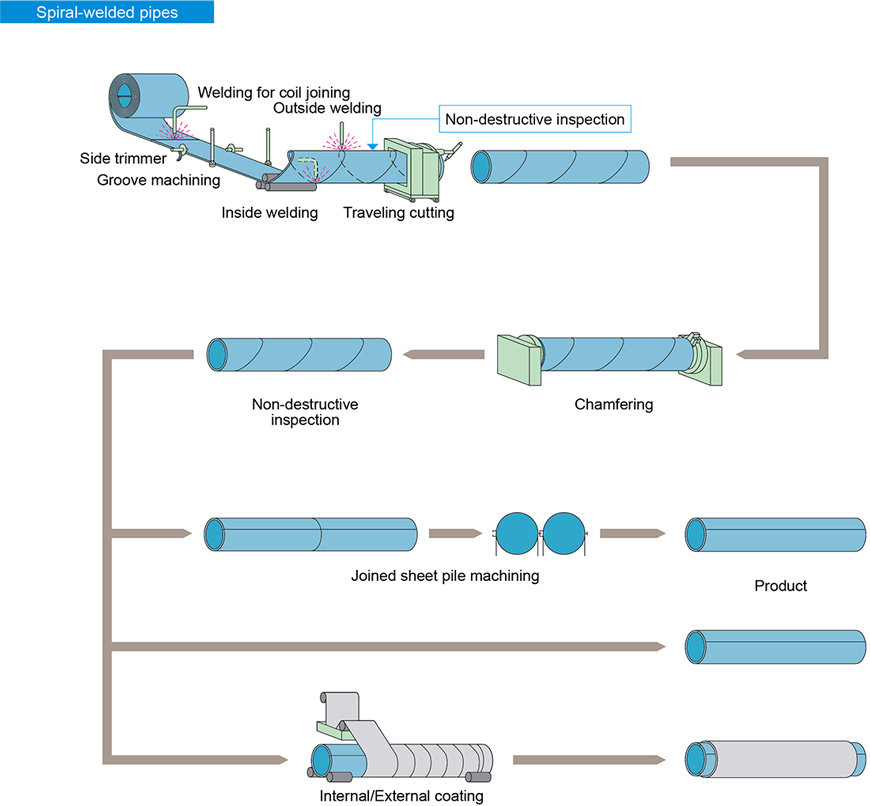

Habka Wax Soo Saarka:Tuubooyinka birta ah ee wareegsan waxaa lagu soo saaraa hab gaar ah oo ku lug leh isticmaalka xarig bir ah. Xarigga waa la furfuraa oo loo sameeyaa qaab wareegsan, ka dibna waxaa lagu dahaadhaa farsamada alxanka qulqulka (SAW). Habkani wuxuu keenaa tolmo joogto ah oo helical ah oo ku teedsan dhererka tuubada.

Naqshadeynta Qaab-dhismeedka:Tolmada helikaalka ah ee tuubooyinka birta ah ee wareegsan waxay bixisaa xoog dabiici ah, taasoo ka dhigaysa kuwo ku habboon u adkeysiga culaysyada iyo cadaadiska sare. Naqshaddani waxay hubinaysaa qaybinta isku midka ah ee walbahaarka waxayna kor u qaadaysaa awoodda tuubooyinka ay u leeyihiin inay iska caabiyaan foorarsiga iyo isbeddelka.

Cabbirka Kala Duwan:Tuubooyinka birta ah ee wareegsan waxay ku yimaadaan dhexroor ballaaran (ilaa 120 Inch) iyo dhumuc, taasoo u oggolaanaysa dabacsanaan codsiyada kala duwan. Badanaa waxaa laga heli karaa dhexroor weyn marka loo eego noocyada kale ee tuubooyinka.

Codsiyada:Tuubooyinka birta ah ee wareegsan waxaa loo isticmaalaa warshado kala duwan sida saliidda iyo gaaska, biyaha, dhismaha, beeraha, iyo horumarinta kaabayaasha dhaqaalaha. Waxay ku habboon yihiin isticmaalka dhulka korkiisa iyo dhulka hoostiisa labadaba.

Iska caabbinta Daxalka:Si loo kordhiyo cimriga, tuubooyinka birta ah ee wareegsan badanaa waxay maraan daawaynta ka hortagga daxalka. Kuwaas waxaa ka mid noqon kara dahaarka gudaha iyo dibadda, sida epoxy, polyethylene, iyo zinc, kuwaas oo ka ilaaliya tuubooyinka walxaha deegaanka iyo walxaha daxalka leh.

Faa'iidooyinka:Tuubooyinka birta ah ee wareegsan waxay bixiyaan faa'iidooyin dhowr ah, oo ay ku jiraan awood culeys sare leh, kharash-oolnimo loogu talagalay tuubooyinka dhexroorka weyn, fududaynta rakibidda, iyo iska caabbinta isbeddelka. Naqshadooda helikaalka ah waxay sidoo kale ka caawisaa daadinta biyaha oo hufan.

LongitudinalVSWareega:Tuubooyinka birta ah ee wareegsan waxaa laga sooci karaa tuubooyinka dhererka leh ee la alxamay iyadoo loo marayo habka wax soo saarka. Iyadoo tuubooyinka dhaadheer la sameeyo oo lagu alxamo dhererka tuubada, tuubooyinka wareegsan waxay leeyihiin tolmo helical ah oo la sameeyay inta lagu jiro wax soo saarka.

Xakamaynta Tayada:Hawsha wax soo saarka iyo xakamaynta tayada ayaa muhiim u ah soo saarista tuubooyin bir ah oo wareegsan oo la isku halleyn karo. Xuduudaha alxanka, joomatariyada tuubooyinka, iyo hababka tijaabada ayaa si taxaddar leh loola socdaa si loo hubiyo u hoggaansanaanta heerarka warshadaha iyo qeexitaannada.

Heerarka iyo Tilmaamaha:Tuubooyinka birta ah ee wareegsan waxaa loo soo saaraa iyadoo la raacayo heerarka caalamiga ah iyo kuwa warshadaha gaarka ah sida API 5L, ASTM, EN, iyo kuwa kale. Heerarkani waxay qeexayaan sifooyinka agabka, hababka wax soo saarka, iyo shuruudaha tijaabada.

Marka la soo koobo, tuubooyinka birta wareegsan waa xal loo isticmaali karo oo waara oo loogu talagalay warshado kala duwan. Hawshooda wax soo saarka ee gaarka ah, xoogga ku dhex jira, iyo helitaankooda cabbirro kala duwan ayaa gacan ka geysta isticmaalkooda baahsan ee kaabayaasha dhaqaalaha, gaadiidka, tamarta, dhismaha dekadaha iyo waxyaabo kaloo badan. Xulashada saxda ah, xakamaynta tayada, iyo tallaabooyinka ilaalinta daxalka ayaa door muhiim ah ka ciyaara hubinta waxqabadka muddada dheer ee tuubooyinka birta wareegsan.

Tilmaamaha

| API 5L: GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: GR.1, GR.2, GR.3 |

| EN 10219-1: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: GR.A, GR.B |

| EN 10217: P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: St37.0, St44.0, St52.0 |

| AS/NZS 1163: Darajada C250, Darajada C350, Darajada C450 |

| GB/T 9711: L175, L210, L245, L290, L320, L360, L390, L415, L450, L485 |

| ASTMA671: CA55/CB70/CC65, CB60/CB65/CB70/CC60/CC70, CD70/CE55/CE65/CF65/CF70, CF66/CF71/CF72/CF73, CG100/CH100/CI100/CJ100 |

| Dhexroor (mm) | Dhumucda Darbiga (mm) | |||||||||||||||||||

| 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | |

| 219.1 | ● | ● | ● | ● | ||||||||||||||||

| 273 | ● | ● | ● | ● | ● | |||||||||||||||

| 323.9 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 325 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 355.6 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| 377 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 406.4 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 426 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 457 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 478 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| 508 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 529 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 630 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 711 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 720 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 813 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| 920 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 1420 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| 1620 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| 1820 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2020 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2220 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| 2500 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 2540 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| 3000 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

Dulqaadka Dhexroorka Dibadda iyo Dhumucda Darbiga

| Heerka Caadiga ah | Dulqaadka Jirka Tuubada | Dulqaadka Tuubada Dhamaadka | Dulqaadka Dhumucda Darbiga | |||

| Dhexroorka Baxsan | Dulqaad | Dhexroorka Baxsan | Dulqaad | |||

| GB/T3091 | OD≤48.3mm | ≤±0.5 | OD≤48.3mm | - | ≤±10% | |

| 48.3 | ≤±1.0% | 48.3 | - | |||

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 | |||

| OD> 508mm | ≤±1.0% | OD> 508mm | -0.8~+3.2 | |||

| GB/T9711.1 | OD≤48.3mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | OD≤273.1mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% | |

| 508 | ≤±1.0% | OD≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% | |

| OD> 941mm | ≤±1.0% | - | - | - | - | |

| GB/T9711.2 | 60 | ±0.75%D~±3mm | 60 | ±0.5%D~±1.6mm | 4mm | ±12.5%T~±15.0%T |

| 610 | ±0.5%D~±4mm | 610 | ±0.5%D~±1.6mm | WT≥25mm | -3.00mm~+3.75mm | |

| OD> 1430mm | - | OD> 1430mm | - | - | -10.0%~+17.5% | |

| SY/T5037 | OD <508mm | ≤±0.75% | OD <508mm | ≤±0.75% | OD <508mm | ≤±12.5% |

| OD≥508mm | ≤±1.00% | OD≥508mm | ≤±0.50% | OD≥508mm | ≤±10.0% | |

| API 5L PSL1/PSL2 | OD <60.3 | -0.8mm~+0.4mm | OD≤168.3 | -0.4mm~+1.6mm | WT≤5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T | |

| 168.3 | ≤±0.75% | 610 | ≤±1.6mm | T≥15.0 | ≤±1.5 | |

| 610 | ≤±4.0mm | OD>1422 | - | - | - | |

| OD>1422 | - | - | - | - | - | |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% | |

| OD≥114.3 | -0.5%~1.0% | OD≥114.3 | -0.5%~1.0% | ≤-12.5% | ||

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% | |||

| DN mm | NB Inji | OD mm | SCH40S mm | SCH5S mm | SCH10S mm | SCH10 mm | SCH20 mm | SCH40 mm | SCH60 mm | XS/80S mm | SCH80 mm | SCH100 mm | SCH120 mm | SCH140 mm | SCH160 mm | SCHXXS mm |

| 6 | 1/8” | 10.29 | 1.24 | 1.73 | 2.41 | |||||||||||

| 8 | 1/4” | 13.72 | 1.65 | 2.24 | 3.02 | |||||||||||

| 10 | 3/8” | 17.15 | 1.65 | 2.31 | 3.20 | |||||||||||

| 15 | 1/2” | 21.34 | 2.77 | 1.65 | 2.11 | 2.77 | 3.73 | 3.73 | 4.78 | 7.47 | ||||||

| 20 | 3/4” | 26.67 | 2.87 | 1.65 | 2.11 | 2.87 | 3.91 | 3.91 | 5.56 | 7.82 | ||||||

| 25 | 1” | 33.40 | 3.38 | 1.65 | 2.77 | 3.38 | 4.55 | 4.55 | 6.35 | 9.09 | ||||||

| 32 | 1 1/4” | 42.16 | 3.56 | 1.65 | 2.77 | 3.56 | 4.85 | 4.85 | 6.35 | 9.70 | ||||||

| 40 | 1 1/2” | 48.26 | 3.68 | 1.65 | 2.77 | 3.68 | 5.08 | 5.08 | 7.14 | 10.15 | ||||||

| 50 | 2” | 60.33 | 3.91 | 1.65 | 2.77 | 3.91 | 5.54 | 5.54 | 9.74 | 11.07 | ||||||

| 65 | 2 1/2” | 73.03 | 5.16 | 2.11 | 3.05 | 5.16 | 7.01 | 7.01 | 9.53 | 14.02 | ||||||

| 80 | 3” | 88.90 | 5.49 | 2.11 | 3.05 | 5.49 | 7.62 | 7.62 | 11.13 | 15.24 | ||||||

| 90 | 3 1/2” | 101.60 | 5.74 | 2.11 | 3.05 | 5.74 | 8.08 | 8.08 | ||||||||

| 100 | 4” | 114.30 | 6.02 | 2.11 | 3.05 | 6.02 | 8.56 | 8.56 | 11.12 | 13.49 | 17.12 | |||||

| 125 | 5” | 141.30 | 6.55 | 2.77 | 3.40 | 6.55 | 9.53 | 9.53 | 12.70 | 15.88 | 19.05 | |||||

| 150 | 6” | 168.27 | 7.11 | 2.77 | 3.40 | 7.11 | 10.97 | 10.97 | 14.27 | 18.26 | 21.95 | |||||

| 200 | 8" | 219.08 | 8.18 | 2.77 | 3.76 | 6.35 | 8.18 | 10.31 | 12.70 | 12.70 | 15.09 | 19.26 | 20.62 | 23.01 | 22.23 | |

| 250 | 10” | 273.05 | 9.27 | 3.40 | 4.19 | 6.35 | 9.27 | 12.70 | 12.70 | 15.09 | 19.26 | 21.44 | 25.40 | 28.58 | 25.40 | |

| 300 | 12" | 323.85 | 9.53 | 3.96 | 4.57 | 6.35 | 10.31 | 14.27 | 12.70 | 17.48 | 21.44 | 25.40 | 28.58 | 33.32 | 25.40 | |

| 350 | 14" | 355.60 | 9.53 | 3.96 | 4.78 | 6.35 | 7.92 | 11.13 | 15.09 | 12.70 | 19.05 | 23.83 | 27.79 | 31.75 | 35.71 | |

| 400 | 16" | 406.40 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 12.70 | 16.66 | 12.70 | 21.44 | 26.19 | 30.96 | 36.53 | 40.49 | |

| 450 | 18" | 457.20 | 9.53 | 4.19 | 4.78 | 6.35 | 7.92 | 14.27 | 19.05 | 12.70 | 23.83 | 29.36 | 34.93 | 39.67 | 45.24 | |

| 500 | 20” | 508.00 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 15.09 | 20.62 | 12.70 | 26.19 | 32.54 | 38.10 | 44.45 | 50.01 | |

| 550 | 22" | 558.80 | 9.53 | 4.78 | 5.54 | 6.35 | 9.53 | 22.23 | 12.70 | 28.58 | 34.93 | 41.28 | 47.63 | 53.98 | ||

| 600 | 24" | 609.60 | 9.53 | 5.54 | 6.35 | 6.35 | 9.53 | 17.48 | 24.61 | 12.70 | 30.96 | 38.89 | 46.02 | 52.37 | 59.54 | |

| 650 | 26" | 660.40 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 700 | 28" | 711.20 | 9.53 | 7.92 | 12.70 | 12.70 | ||||||||||

| 750 | 30” | 762.00 | 9.53 | 6.35 | 7.92 | 7.92 | 12.70 | 12.70 | ||||||||

| 800 | 32" | 812.80 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 850 | 34” | 863.60 | 9.53 | 7.92 | 12.70 | 17.48 | 12.70 | |||||||||

| 900 | 36” | 914.40 | 9.53 | 7.92 | 12.70 | 19.05 | 12.70 | |||||||||

| DN 1000mm iyo wixii ka sareeya Dhumucda tuubada ugu badnaan 25mm | ||||||||||||||||

Heerka & Darajada

| Heerka Caadiga ah | Darajooyinka Birta |

| API 5L: Qeexitaanka Tuubada Khadka | GR.B, X42, X46, X52, X56, X60, X65, X70, X80 |

| ASTM A252: Qeexitaanka Caadiga ah ee Tuubooyinka Birta ee Alxanka leh iyo kuwa aan kala go 'lahayn | GR.1, GR.2, GR.3 |

| EN 10219-1: Qaybaha godan ee qaab-dhismeedka qabow ee alxanka leh ee birta aan dahaarka lahayn iyo kuwa hadhuudhka wanaagsan | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| EN10210: Qaybaha dhismaha ee kulul ee la dhammeeyay ee birta aan birta ahayn iyo kuwa hadhuudhka wanaagsan | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H |

| ASTM A53/A53M: Tuubo, Bir, Madow iyo Kuleyl lagu shubay, Zinc lagu dahaadhay, Alxan leh oo aan sinayn | GR.A, GR.B |

| EN 10217: Tuubooyinka Birta ah ee la alxamay ee loogu talagalay Ujeeddooyinka Cadaadiska | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 |

| DIN 2458: Tuubooyinka iyo Tuubooyinka Birta ah ee Laalaaban | St37.0, St44.0, St52.0 |

| AS/NZS 1163: Heerka Australia/New Zealand ee Qaybaha Birta Qaab-dhismeedka Qabow ee Qaab-dhismeedka ah | Darajada C250, Darajada C350, Darajada C450 |

| GB/T 9711: Warshadaha Batroolka iyo Gaaska Dabiiciga ah - Tuubada Birta ah ee Tuubooyinka | L175, L210, L245, L290, L320 , L360, L390 , L415, L450 , L485 |

| AWWA C200: Tuubada Biyaha Birta ah 6 Inji (150 mm) iyo ka weyn | Bir Kaarboon ah |

Habka Wax Soo Saarka

Xakamaynta Tayada

● Hubinta Walxaha Cayriin

● Falanqaynta Kiimikada

● Tijaabada Farsamada

● Kormeerka Aragga

● Hubinta Cabbirka

● Tijaabada Laabista

● Tijaabada Saamaynta

● Tijaabada Daxalka ee Isku-dhafka ah

● Baaritaan aan burburin (UT, MT, PT)

● Shahaadada Habka Alxanka

● Falanqaynta Qaab-dhismeedka Yaryar

● Tijaabada Dab-shidka iyo Fiditaanka

● Tijaabada Adkaanta

● Tijaabinta Cadaadiska

● Tijaabada Metalografiga

● Baaritaanka Daxalka

● Baaritaanka Hadda ee Eddy

● Kormeerka Rinjiga iyo Dahaarka

● Dib u Eegista Dukumentiyada

Isticmaalka & Codsiga

Tuubooyinka birta wareegsan waa kuwo la isticmaali karo oo si weyn loogu isticmaalo warshado kala duwan sababtoo ah astaamo iyo faa'iidooyinkooda gaarka ah. Waxaa lagu sameeyaa isku-xidhka xargaha birta si loo abuuro tuubo leh tolmo wareegsan oo joogto ah. Waa kuwan qaar ka mid ah codsiyada caadiga ah ee tuubooyinka birta wareegsan:

● Gaadiidka Dareeraha: Tuubooyinkani waxay si hufan ugu dhaqaajiyaan biyaha, saliidda, iyo gaaska masaafada dheer ee dhuumaha sababtoo ah dhismahooda aan kala go 'lahayn iyo xooggooda sare.

● Saliid iyo Gaas: Muhiim u ah warshadaha saliidda iyo gaaska, waxay qaadaan saliidda cayriin, gaaska dabiiciga ah, iyo alaabada la safeeyey, iyagoo u adeegaya baahiyaha sahaminta iyo qaybinta.

● Tuurista: Tuubooyinka aasaaska ee mashaariicda dhismaha waxay taageeraan culaysyo culus oo ku yimaada dhismayaasha sida dhismayaasha iyo buundooyinka.

● Isticmaalka Qaab-dhismeedka: Iyagoo loo adeegsado dhismaha qaab-dhismeedka, tiirarka, iyo taageerooyinka, waaradoodu waxay gacan ka geysataa xasilloonida qaab-dhismeedka.

● Biyo-mareennada iyo Biyo-mareennada: Waxaa loo isticmaalaa nidaamyada biyaha, iska caabbinta daxalka iyo gudaha siman waxay ka hortagaan inay xirmaan oo ay wanaajiyaan socodka biyaha.

● Tuubooyinka Farsamada: Wax soo saarka iyo beeraha, tuubooyinkani waxay bixiyaan xalal kharash-ool ah oo adag oo loogu talagalay qaybaha.

● Badda iyo Badda: Deegaannada adag, waxaa loo isticmaalaa dhuumaha biyaha hoostooda, goobaha xeebaha, iyo dhismaha detty-ga.

● Macdan qodista: Waxay gudbiyaan agab iyo wasakh marka ay ku jiraan howlaha macdanta ee adag sababtoo ah dhismahooda adag.

● Biyo-siinta: Ku habboon dhuumaha dhexroorka weyn ee nidaamyada biyaha, iyagoo si hufan u qaadaya mugga biyaha ee muhiimka ah.

● Nidaamyada Tamarta Dhulka: Waxaa loo isticmaalaa mashaariicda tamarta dhulka, waxayna qabtaan wareejinta dareeraha u adkaysta kulaylka ee u dhexeeya kaydka iyo warshadaha korontada.

Dabeecadda kala duwan ee tuubooyinka birta ah ee wareegsan, oo ay weheliso xooggooda, cimri dhererkooda, iyo la qabsigooda, ayaa ka dhigaysa qayb muhiim ah oo ka mid ah warshado iyo codsiyo kala duwan.

Xirmooyinka iyo Rarista

Baakad:

Habka xidhitaanka tuubooyinka birta ah ee wareegsan waxay ku lug leedahay dhowr tallaabo oo muhiim ah si loo hubiyo in tuubooyinka si ku filan loo ilaaliyo inta lagu jiro rarista iyo kaydinta:

● Xidhmada Tuubooyinka: Tuubooyinka birta wareegsan ayaa badanaa la isku xidhaa iyadoo la adeegsanayo xarigyo, xarigyo bir ah, ama habab kale oo lagu xidho oo ammaan ah. Xidhmadu waxay ka hortagtaa in tuubooyinka shaqsiga ah ay dhaqaaqaan ama ay ku wareegaan baakadda dhexdeeda.

● Ilaalinta Dhamaadka Tuubooyinka: Dabool balaastig ah ama dabool ilaalin ah ayaa la saaraa labada daraf ee tuubbooyinka si looga hortago waxyeelada soo gaarta darafyada tuubbooyinka iyo dusha sare ee gudaha.

● Biyo-celin: Tuubooyinka waxaa lagu duubay walxo biyo-celin ah, sida balaastigga ama duubka, si looga ilaaliyo qoyaanka inta lagu jiro gaadiidka, gaar ahaan marka la dhoofinayo dibadda ama badda.

● Suufka: Agab dheeraad ah oo suufka lagu xidho, sida xumbada lagu xidho ama qalabka barkimooyinka, ayaa laga yaabaa in lagu daro inta u dhaxaysa tuubooyinka ama meelaha nugul si loo nuugo shoogga iyo gariirka.

● Calaamadaynta: Xirmo kasta waxaa lagu calaamadeeyay macluumaad muhiim ah, oo ay ku jiraan qeexitaannada tuubooyinka, cabbirrada, tirada, iyo meesha loo socdo. Tani waxay ka caawisaa aqoonsashada iyo maaraynta fudud.

Rarista:

● Tuubooyinka birta ah ee wareega ee rarista waxay u baahan yihiin qorsheyn taxaddar leh si loo hubiyo gaadiid badbaado leh oo hufan:

● Habka Gaadiidka: Doorashada qaabka gaadiidka (waddo, tareen, bad, ama hawada) waxay ku xiran tahay arrimo ay ka mid yihiin masaafada, degdegga, iyo helitaanka meesha loo socdo.

● Konteenareynta: Tuubooyinka waxaa lagu shubi karaa weelasha rarista caadiga ah ama weelasha raafka ee gaarka ah. Konteenareynta waxay ka ilaalisaa tuubooyinka walxaha dibadda waxayna bixisaa jawi la xakameeyey.

● Sugidda: Tuubooyinka waxaa lagu xiraa weelasha iyadoo la adeegsanayo habab ku habboon oo lagu xidho, sida hagaajinta, xannibaadda, iyo garaacista. Tani waxay ka hortagtaa dhaqdhaqaaqa waxayna yareysaa khatarta waxyeelada inta lagu jiro safarka.

● Dukumentiyada: Dukumentiyada saxda ah, oo ay ku jiraan biilasha, liisaska baakadaha, iyo caddeynta rarista, ayaa loo diyaariyey ujeeddooyinka nadiifinta kastamka iyo dabagalka.

● Caymiska: Caymiska xamuulka waxaa badanaa la helaa si loo daboolo khasaaraha ama waxyeelada suurtagalka ah inta lagu jiro safarka.

● La socodka: Inta lagu jiro habka rarista, tuubooyinka waxaa lagu raadraaci karaa iyadoo la adeegsanayo GPS iyo nidaamyada raadraaca si loo hubiyo inay ku socdaan wadada saxda ah iyo jadwalka.

● Kastamka Nadiifinta: Dukumenti sax ah ayaa la bixiyaa si loo fududeeyo nadiifinta kastamka ee dekadda ama xadka loo socdo.

Gunaanad:

Xirmo habboon iyo rarista tuubooyinka birta ah ee wareegsan ayaa lagama maarmaan u ah ilaalinta tayada iyo hufnaanta tuubooyinka inta lagu jiro gaadiidka. Raacitaanka dhaqamada ugu wanaagsan ee warshadaha ayaa hubinaya in tuubooyinku ay gaaraan meeshii ay u socdeen iyagoo xaaladdoodu ugu fiican tahay, diyaar u ah rakibidda ama farsamaynta dheeraadka ah.